Used Air Bottle Rinsers For Sale

At SIGMA Equipment, our team is here to help you find the right equipment to match your specific packaging needs. Whether you’re looking for a single machine or a full system, we can guide you to the right air bottle rinser and support your project with shop services that make it easier to upgrade or build a new production line.

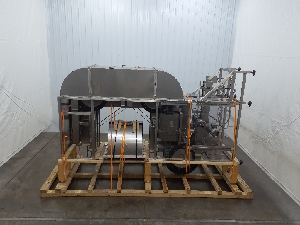

Arrowhead Lowerator And Air Bottle Rinser

Used Arrowhead Lowerator With Air Rinser: Designed to accept containers from a depalletizer, invert them, a ir rinse, then re- invert Adjustment range: 2-6.5 inches Infeed conveyor: ...

Kaps-All Orientainer AC-I Bottle Air Rinser

Used Kaps-All AC-I Bottle Air Rinser: Bottle diameters: Approximately 0.5-6 inches Bottle gripper belts Bottle inverter Ionized air to clean the bottles Bottle re-inverter Manual crank...

E Pack Machinery 12 Head Inline Air Bottle Cleaner Blower

Used E Pack Machinery 12 Head Inline Air Bottle Cleaner Blower with: The EPak Air Bottle Rinser is a high-efficiency machine designed to clean and rinse bottles before filling. Using a...

Bevco M150 Bottle/Can Gripper And Air Rinser With Ionized Air

Bevco’s gripper-style Rinsers are able to rinse a wide variety of container types, including round, square, oval, tapered, and other bottle shapes, in many different materials (glass, PET, HDPE...

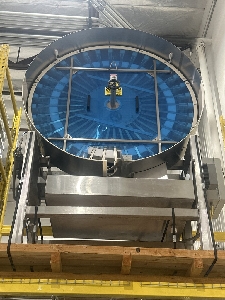

McBrady Model #200 Orbit 48"D Ionized Air Rinser Up To 200 Bottles Per Minute

Used Mcbrady Bottle Rinser: Rinsing style: ionized air Output: up to 200 bottles per minute depending on the application Bottle sizes (change part dependent): 5cc-2.5 gallons Bottle styles...

Paxton Power Dry Ionized Air Bottle Dryer/Rinser With Variable Frequency Drive

Paxton’s PowerDry drying system sets the standard for complete blow-off cleaning and drying systems. This affordable system uses significantly less energy than a compressed air system (or thermal...

Apex Filling Systems 8 Station Air Rinser

Used Apex Filling Systems 8 Station Air Rinser with: Photo sensor and counter system Vacuum dust suction nozzles Coned, self-centering neck guides Automatic pin-style indexing system 80 -...

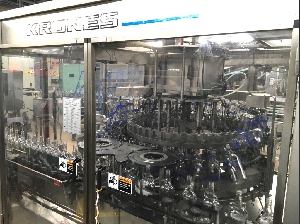

Krones Variojet 45 Valve Air Rinser

Used Krones Variojet Air Rinser with: Speed: up to 130 bottles per minute, depending on application Rinsing valves: 45 Ionized air rinsing Infeed timing screw Touchscreen controls ...

Inline 108" Long 10-Nozzle RSC Rinser and Indexing Conveyor

Used Indexing Conveyor with Air Rinse with: Conveyor dimensions: Length: 108 inches Width: 4.5 inches Guard rail dimensions: Rail 1 height: 4 inches Rail 2 height: 3 inces 10 Nozzle Air...

Nercon Upswing Stainless Steel Lowerator Air Bottle Rinser

Used Nercon Lowerator with: Cleans with deionized air Infeed: Infeeds through the side Infeed height: 78 inches Discharge: End discharge Discharge height: approximately 40...

E-PAK 18 Station Inline Air Bottle Rinser Cleaner

Used E-PAK Machinery Air Bottle Rinser with: Inline air bottle rinser 18 stations with diving heads Maximum container diameter: 2 11/16 inches Adjustable bottle sensors Lexan guarding ...

Kaps All Model AC-12 Bottle Air Cleaner

Used Kaps All Model AC-12 Bottle Air Cleaner with: Runs up to 80 bottles per minute 6 fill nozzles Conveyor: 4.5 inches wide x 60 inches long 1 horsepower motor Stainless steel...

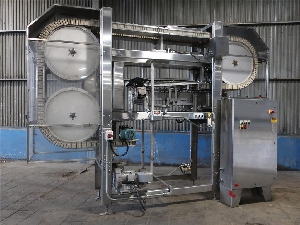

Krones 45 Valve Variojet Rotary Ionized Air Rinser

Used Krones Air Rinser with: 45 head rinsing system Ionized air rinsing Last ran 750 mililiter glass bottles Infeed timing screw Operator PanelView 1000 Last running 130 bottles per minute...

Krones Variojet 45 Valve Bottle Rinser

Used Krones Bottle Rinser with: Application: cleaning the inside of glass or plastic containers Output: up to 130 bottles per minute Number of rinser valve: 45 Rinse medium: ionized air rinse...

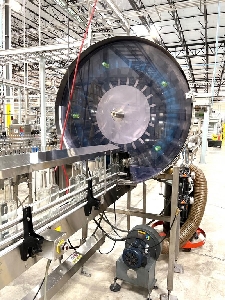

McBrady 220 Orbital Bottle Cleaner

Used McBrady Bottle Rinser with: Output: up to 300 bottles per minute Wheel/drum diameter: 54 inches Includes drive motor Container types: Glass Metal Plastic Composite containers Duplex...

About Air Bottle Rinsers

This type of bottle rinsing equipment uses air to clean and remove dust and other debris from glass, plastic, metal and other containers. By spraying the interior of the container, a vacuum is created to remove contaminates. Removing contaminates helps ensure product quality and security. Air bottle cleaners can be designed to use either normal compressed air or deionized air.

Start Your ProjectHave more to sell? Learn about SIGMA's equipment selling solutions, including valuation, safe removal, warehousing, and targeted marketing to maximize your equipment's resale value.