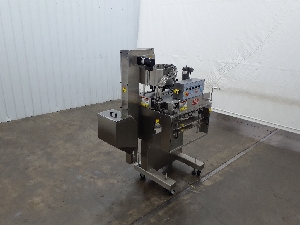

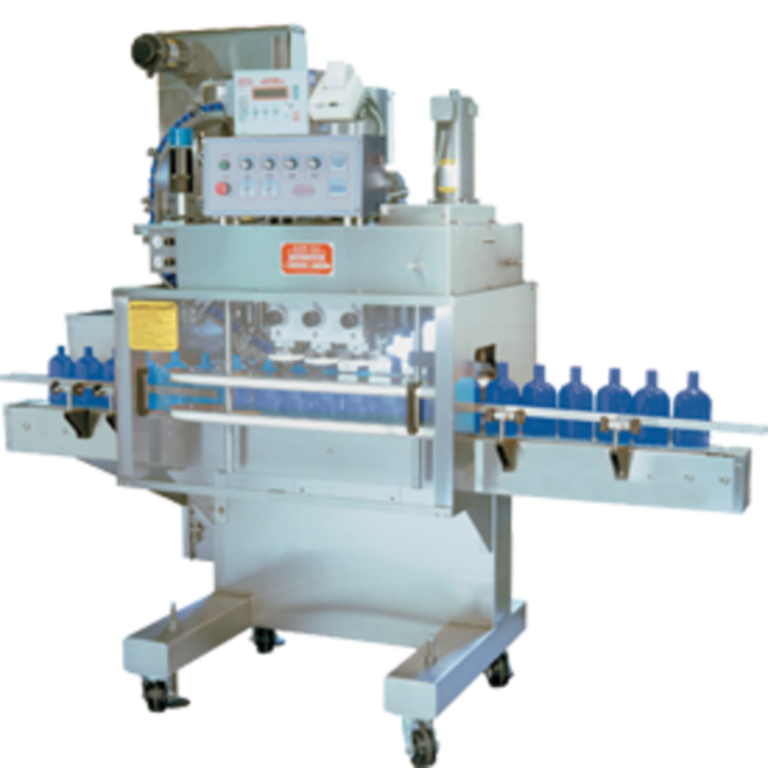

Kaps-All Packaging Systems, Inc. A6

Manufacturer:Kaps-All Packaging Systems, Inc.

Model:A6

Category:Spindle Capper

The Kaps-All A6 Spindle Capper is an automatic capping machine designed for applying screw caps onto a variety of containers. The A6 is equipped with adjustable spindles negating the need for change parts. This system accommodates bottles of different shapes and sizes, making it ideal for industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals.

Description

- Production speed: up to 200 containers per minute depending on the size of the cap, container and application

- Screw cap diameter range:

- Minimum: 8 mm

- Maximum: 120 mm

- Pilfer evident and child-resistant cap diameter range:

- Minimum: 13 mm

- Maximum: 70 mm

- Maximum container size: 2.5 gallons

- Cap supply hopper capacity: 3.5 cubic feet

- One pair of stainless steel bottle gripper belt housings with belts and drives

- Variable speed drive

- No bottle/No cap sensor

- Mounted on four swivel casters

- Threaded screw leveling feet

- Stainless steel construction

- Air requirements: 2 to 4 cubic feet per minute

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

Equipment Rental Overview

Renting from SIGMA Equipment offers a cost effective solution for short to mid term processing and packaging needs. Our standard rental agreement provides flexibility while ensuring professional standards for transport, insurance, and operational use.

How it Works: The Rental Process

Step 1

Complete Credit Application

Submit a quick credit application. Most approvals are completed within one business day.

Step 2

Sign Rental Agreement

Once approved, we send the agreement. First month's rent and a refundable deposit are due upfront (Minimum term: 2 months).

Step 3

Invoice & Schedule Freight

Once payment is received, freight is scheduled. Items marked "Ready to Ship" are typically ready for pickup within 72 hours.

Key Rental Highlights & Terms:

- Minimum Rental Period: Two months

- Initial Payment: First month's rent plus a refundable deposit

- Rental Credits: 50% of on-time rental payments can be applied toward the purchase price

-

Equipment Condition: Generally provided as is and may require minor repairs or change parts.

*Equipment specifically marked "Ready to Run" includes a 14-day Right of Return. - Shipping: Lessee responsible for dedicated transport both ways (no LTL carriers). "Ready to Ship" items are typically ready for pickup within 72 hours of payment.

- Return Requirements: Must be returned on original skid; early returns may incur fees

- Insurance: $1,000,000 liability and full coverage on equipment required

- Maintenance: Lessee handles operation, setup, upkeep, and consumables during rental

A SIGMA team member will gladly answer any additional questions regarding specific lead times or terms—click the Rent Now button above.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.