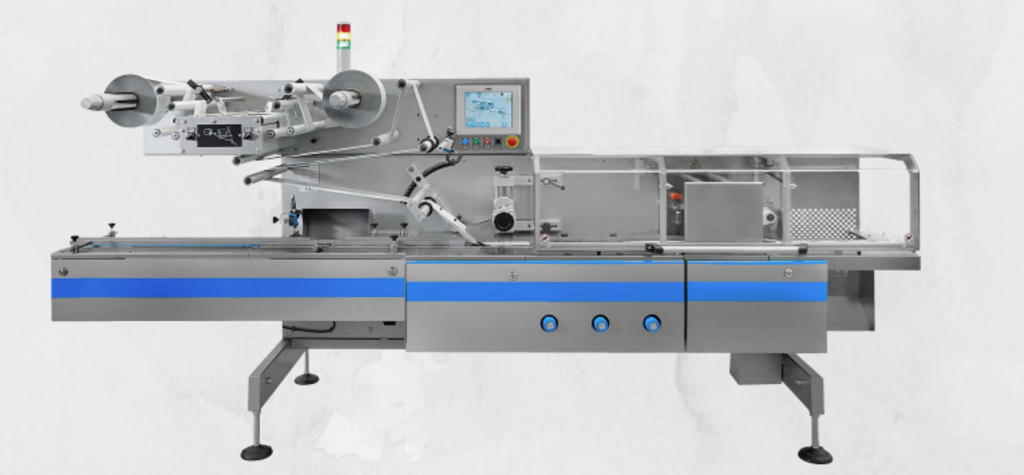

Viking Masek Global Packaging Technologies Pack 900 LTS Flow Wrapper

Manufacturer:Viking Masek Global Packaging Technologies

Model:Pack 900 LTS Flow Wrapper

The Viking Masek Pack 900 LTS Flow Wrapper is designed for high-speed, versatile packaging in various industries. Combining advanced technology with robust engineering, this machine delivers exceptional performance in wrapping products with precision and efficiency. Whether you’re packaging food, pharmaceuticals, or other consumer goods, the 900 LTS offers superior flexibility, easy operation, and reliable sealing. With its customizable features, this flow wrapper adapts to your specific production needs, ensuring consistent, high-quality packaging every time.

Description

Main Technical Characteristics:

• Product flow from left to right, looking from the operator’s point of view. (Inverted right to left execution,

available upon request).

• Ergonomic design and easy accessibility, in accordance with the international standards of hygiene and

security for a quick and easy cleaning of the machine, and in compliance with the CE safety regulations.

• Machine frame composed by a main body of electro-welded carbon steel plate assembled with a vertical

main plate, on which the machine groups are fixed on cantilever, that easy and minimize the stopping times

for both the cleaning and preventive maintenance operations.

• Electrical cabinet integrated within the machine frame, in accordance with the in-force CE regulations of

electromagnetic compatibility and low tension.

• Hinged doors with safety interlocks in the rear side of the frame, to access to both the main driving groups

and the electrical cabinet.

• Transparent safety guard with security switch which stops the machine in case of opening, and covers all

moving parts, from the forming box up to the outfeed belt.

• All parts in contact with the product are made of stainless steel and /or food grade plastics.

• All mechanical components manufactured by Viking Masek are laser coded, for a quick and easy spare

identification.

• Main movements carried out through motors directly coupled to motion groups. This eliminates the needs

of intermediate transmissions and minimize maintenance operations, as well as decrease the machine

noise level.

• The Pack 900 LTS is controlled by means of 6 independent Servomotors:

▪ Infeed conveyor > Film Unwinder > Longitudinal sealing group > Transversal sealing-cutting group (Vertical movement)

▪ Transversal sealing-cutting group (Horizontal. Mov.) > Outfeed belt

• Rockwell electronic

• 10” Touch screen operator’s terminal, display 800 x 600, TFT, true color, with “Ethernet” connection, for

machine operation and control.

Technical Data:

- Seal jaw (width) 250 mm

- Product Length (mm) 100- unlimited

- Product Width (mm) 10-170

- Product Height (mm) 1-140

- Product Memories 40

- Mechanical speed (ppm) up to: 120

- Film speed (mpm) up to: 30

- Max. Reel Width (mm) 500

- Max. Reel Diameter (mm) 300

- Core Diameter (mm) 76

- Power Supply: 480V 3 phase (50/60 Hz)

- Max. Power (depending on conf.) Between 6 & 8 kW

- Air Consumption (depending on conf.) 50 l/min. approx. at 6 bar

- Ethernet connection Available

- Noise Level Less than 85 dB (A)

- Color Silver Metallic Grey RAL 9007

- Dimensions L x W x h (mm) 4650 x 1345 x 1970

- Weight (depending on configuration) Between 1200 & 1500 Kg

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.