Used Fill Level Detectors & Dud Detectors For Sale

At SIGMA Equipment, our team is here to help you find the right equipment to match your specific packaging needs. Whether you’re looking for a single machine or a full system, we can guide you to the right fill level detector and support your project with shop services that make it easier to upgrade or build a new production line.

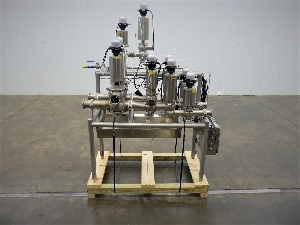

Pentair Intellitop 2.0 Stainless Steel Flow Meters

Used Pentair Intellitop Flow Meters with: Pentair Südmo’s innovation in intelligent communication (valve control unit intellitop 2.0) is designed specifically to increase plant efficiency by...

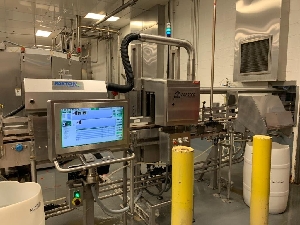

Heuft Spectrum Tx Bottle and Can Inspector Up to 72,000 Bottles Per Hour

Used Heuft Spectrum TX Inspection with: Production speed: 72,000 cans per hour Previous application: glass bottles Full can inspection Fill level control Photo eye detection Inspection area...

CIVision LOMAX P Inspection System

Used CIVision LOMAX P Inspection System with: High-speed, stand alone package inspection system which automatically inspects labels and cap closures on nearly any type of bottle, vial, box or...

Pressco Stainless Steel Fill Height Detector

Used Pressco Fill Level Dector with: Multi-camera detector 360° View around filled, capped bottles Monitors fill level and correct closure Currently set up for 16 ounce & 2 liter bottles...

About Fill Level Detectors

This equipment is used in primarily beverage or food industries. Fill level detectors determine an empty or improperly filled container and reject it. They also may check for leaks and damaged containers.

Start Your ProjectHave more to sell? Learn about SIGMA's equipment selling solutions, including valuation, safe removal, warehousing, and targeted marketing to maximize your equipment's resale value.