Used Front Back Neck Glue Labelers For Sale

At SIGMA Equipment, our team is here to help you find the right equipment to match your specific packaging needs. Whether you’re looking for a single machine or a full system, we can guide you to the right front, back, neck glue labeler and support your project with shop services that make it easier to upgrade or build a new production line.

Kosme Adhesive Compact 440 4T S2 E2 Self Adhesive Pressure Sensitive Rotary Labeler

Used Kosme Adhesive Compact Rotary Labeler with: Production speed: up to 3000 bottles per hour, depending on application Label dimensions (inches): Maximum length: 12.4 Core diameter: 3 Max...

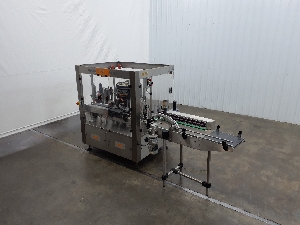

Neri RO800 Automatic Stainless Steel Rotary Cut Stack and Roll Fed Labeler

Used Neri RO800 Labeler with: 2 labeling stations: Cut and stack Roll fed 8 bottle stations Right to left product flow Timing screw and star wheel infeed Touch screen HMI Stainless steel...

B&H Marathon XLA Hot Melt Roll Fed Labeler

Used Hot Roll Fed Labeler with: Allen Bradley Control Logix Kinetic 6000 servo controls Panelview plus 6000 HMI Nordson ALTABlue 10 Glue System Output: 600 beats per minute

Krones Universella Cold Glue Labeler

Used Krones Universella Cold Glue Labeler with: High speed rotary cold glue labeler Maximum Machine output: 24,000 containers per hour One or two labelling stations, each capable of attaching...

About Front, Back, Neck Glue Labelers

This type of glue labeler applies pre-cut labels to products. As products travel down the line, the labeler dispenses the labels onto both sides of the product. The machine usually unwinds the labels from a roll, dispensing the labels on the product (usually bottles), and winding up the leftover backing. A flap, brush, or roller then slides across the labels, ensuring that they are firmly attached. Products such as beer and ketchup bottles use this application.

Start Your ProjectHave more to sell? Learn about SIGMA's equipment selling solutions, including valuation, safe removal, warehousing, and targeted marketing to maximize your equipment's resale value.