Used Pipeline Metal Detectors For Sale

At SIGMA Equipment, our team is here to help you find the right equipment to match your specific packaging needs. Whether you’re looking for a single machine or a full system, we can guide you to the right pipeline metal detector and support your project with shop services that make it easier to upgrade or build a new production line.

Loma IQ2 Flow Through Metal Detector

Used Loma IQ2 Flow Through Metal Detector with: Aperture diameter: 2 inches Mounted on casters and adjustable legs Stainless steel frame Push button controls Alarm sound Electrical...

2014 Loma IQ4 Stainless Steel Pipeline Metal Detector

Used Loma Pipeline Metal Detector with: Pipe diameter: 4.0 inches (ID) Direction of operation: Right-to-left Connection type: Tri-clamp Construction material: 304 Stainless Steel Variable...

Loma IQ4 4" Diameter Pipeline Metal Detector with Reject Valve

Pipeline diameter: 4 inches Detection capabilities: Ferrous: 2.5 mm Non-Ferrous: 3 mm Stainless steel: 3.5 mm Lee Ball style reject valve Variable frequency range: 200 - 882 kHz Touch screen...

Anritsu 18" Wide x 7" Tall Metal Detector Conveyor

Used Anritsu 18" Wide x 7" Tall Metal Detector Conveyor with: Working aperture: 18 inches wide x 7 inches tall Conveyor dimensions: 13.5 inches wide x 29 inches long Working height from ground: 32...

Loma IQ4 2" Diameter High Temperature Pipeline Metal Detector

Pipeline diameter: 2 inches Product temperature: 195° Density: 70,000 pounds per cubic foot High-Temperature Polysulfone (PSU) product pipe construction Detection capabilities: Ferrous: 1.5 mm...

Cassel Shark 2A GF0200 Flow Through Metal Detector

Used Cassel Shark 2A GF0200 Flow Through Metal Detector with: Aperture diameter: 200 millimeters Digital readout Automatic reject valve Through tube length: 36 inches Control box rated for IP66...

Safeline Mettler Toledo 2.5" Diameter Pipeline Metal Detector

Used Safeline Metler Toledo 2.5" Diameter Pipeline Metal Detector with: Working aperture opening: 2.5 inches Pipe length: 32 inches Total aperture: 4 inches Air supply: 80 PSI Rated for up to...

Safeline Signature Pipeline Metal Detector, 3" Diameter

Used Safeline Metal Detector with: Application: inspection of liquids, pastes, slurries, etc. Pipeline capacity: Aperture: 3 inches Tube length: 22 inches Tri-clamp S-line fittings...

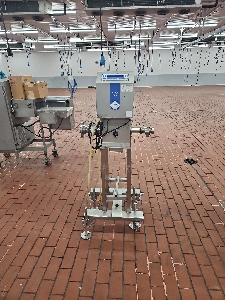

Safeline 4.25" Diameter Pipeline Metal Detector with Reject Valve on Stainless Stand

Used Safeline Pipeline Metal Detector with: Aperture dimensions: 6 inches x 6 inches Pipe diameter: 4.25 inches Pneumatic gate dump valve with light Standard module Hardware version: V3M/MT...

Cassel 6 Inch Food Grade Pipeline Metal Detector

Used Cassel Pipeline Metal Detector with: 6 inch diameter through tube 36 inches long 8 inch total diameter Pneumatic reject valve Digital touch pad operator Food grade sanitary stainless...

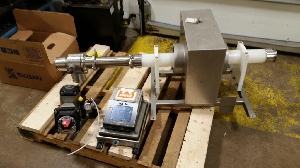

Eriez Tube Liquid Metal Detector 2.5 Inch Diameter

Used Eriez Metal Detector with: Last running dairy products Pipeline: Outer diameter: 3.5 inches Internal diameter: 2.5 inches Electric requirements: Voltage: 100-240V Phase: 1 ...

Fortress Phantom Pipline Metal Detector 3" Dia

Used Fortress Metal Detector with: Application: horizontal orientation for detecting contaminants in pumpable foods Diameter: 3 inches Detectable: Ferrous Non-ferrous Stainless steel ...

Mettler Toledo Safeline 3" Pipeline Metal Detector

Used Mettler Toledo Metal Detector with: Pipeline dimensions: Aperture: 3 inches Length: 22 inches Includes reject system Tri-clamp S-line fittings Stainless steel construction

About Pipeline Metal Detectors

Pipeline metal detectors are used in the food production industries where it is necessary to inspect liquids, pastes and other flowing products as they pass through the processing pipelines. When metal is detected, a reject valve opens, allowing the product with metal to exit. Metal detectors are used to detect even the smallest pieces of metal. They are usually put in a packaging or processing line as a safety check as the products move through the line. Different products require different methods of metal detection.

Start Your ProjectHave more to sell? Learn about SIGMA's equipment selling solutions, including valuation, safe removal, warehousing, and targeted marketing to maximize your equipment's resale value.