Description

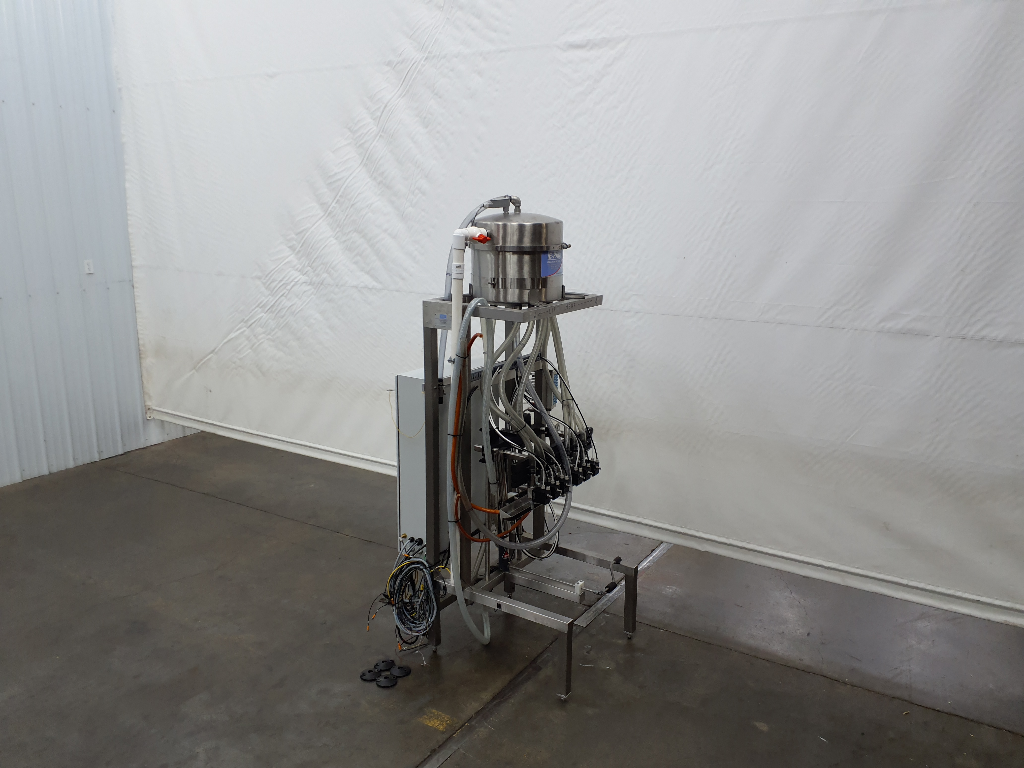

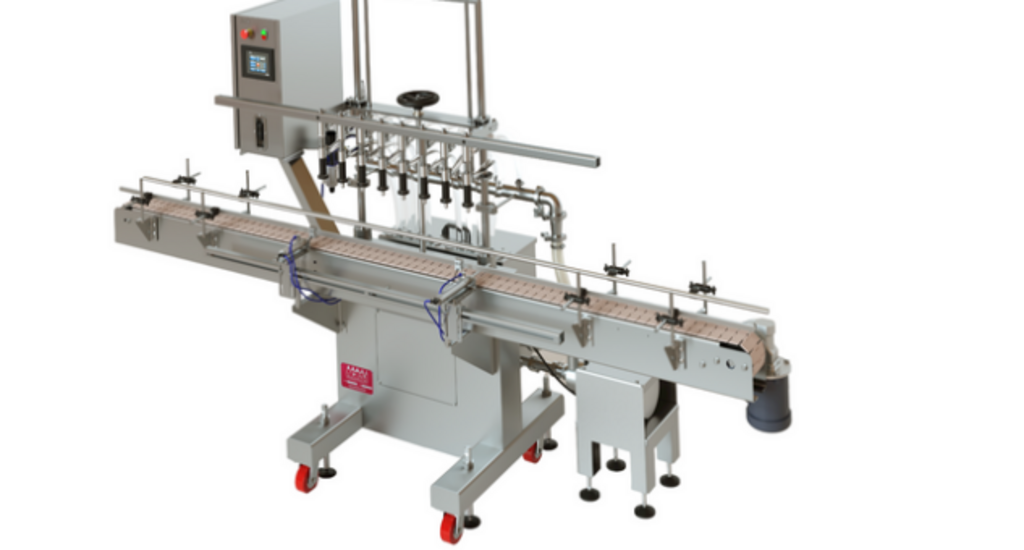

The Acasi GI3000 Automatic Pressure Overflow Filler is a high-precision, efficient solution for filling liquids into a variety of container types. Designed for accuracy and versatility, the GI3000 uses advanced pressure overflow technology to ensure consistent fill levels, even with foamy or low-viscosity products. Its robust stainless steel construction and user-friendly interface make it ideal for industries such as food, beverage, cosmetics, and chemicals. With customizable features and high-speed operation, the GI3000 enhances productivity while maintaining top-tier performance and reliability for your packaging line.

Main Component features:

- 96 Gallon per minute, 1 Hp, 3phase, 316 stainless steel centrifugal pump.

- Hardened Stainless steel calibrated shafts with linear bearings for nozzle rack movement smoothness and durability.

- 10 inch stroke air cylinder with magnetic sensors for nozzle up and down movement.

- 316L Stainless steel sanitary check valve mounted on pump.

- Hand wheel and shaft mounted stoppers for height and stroke adjustment.

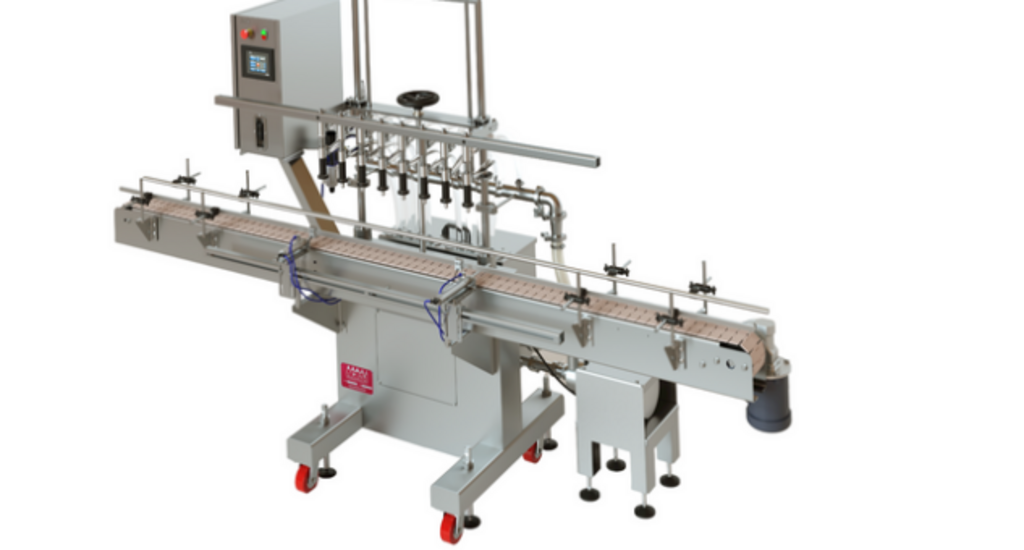

Standard features:

- Nozzle spacing fully adjustable through top screw.

- Container height adjustment from 1 to 16 inches high.

- Nozzle stroke adjustments from 0 to 10 inches.

- Entry and exit bottle gating cylinders adjustable, sideways, up and down and inside and outside.

- Will work with plastic or glass containers.

- No change parts needed for various types of containers.

- Air filter-regulator and safety lockout valve included.

- Spacing and additional bottle control obtained by flow controls mounted on air gating cylinder

Equipment Included in price:

-

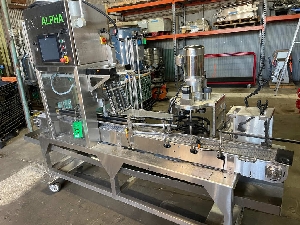

GI-3300 Base filling machine platform, with OMRON touch screen control

panel color display - without nozzles, conveyor, or additional options –

220V -

Pressure Overflow Nozzles manufactured in 316L stainless steel (available

sizes: 3/8-, 1/2-, 5/8-, or 3/4-inch diameter) (6) -

PLC controlled, pneumatic driven drip tray (1)

-

Mechanical valve actuated by 5-inch stainless steel float - Mounted on side

of tank – Level control (1) -

Pneumatic actuated ball valve – Product in-feed control (1)

-

10 Ft. Conveyor, 4.5 in. wide acetyl chain, with speed control installed in

filling machine ́s electric panel (1) -

CRATING

Wooden closed crate- GI 3300

Electric and pneumatic requirements:

- 220 Volts, 60Hz, 10 Amps.

- 5 CFM @ 80 p.s.i.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.