Description

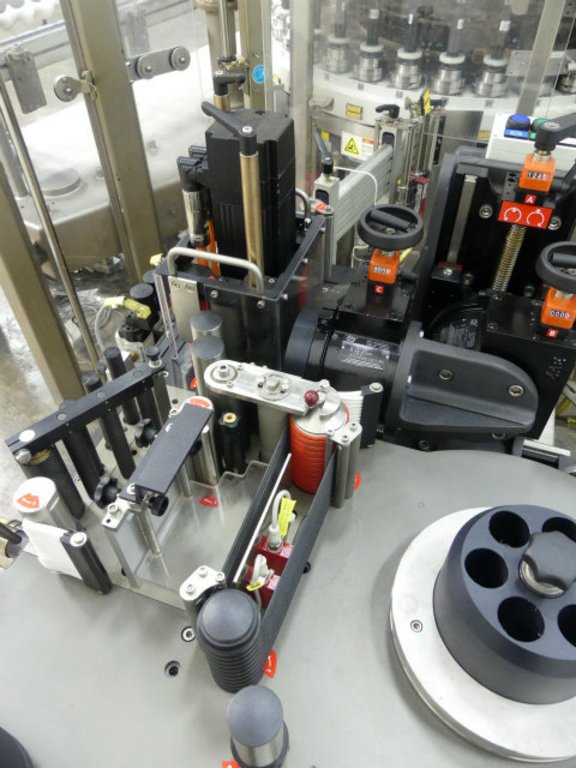

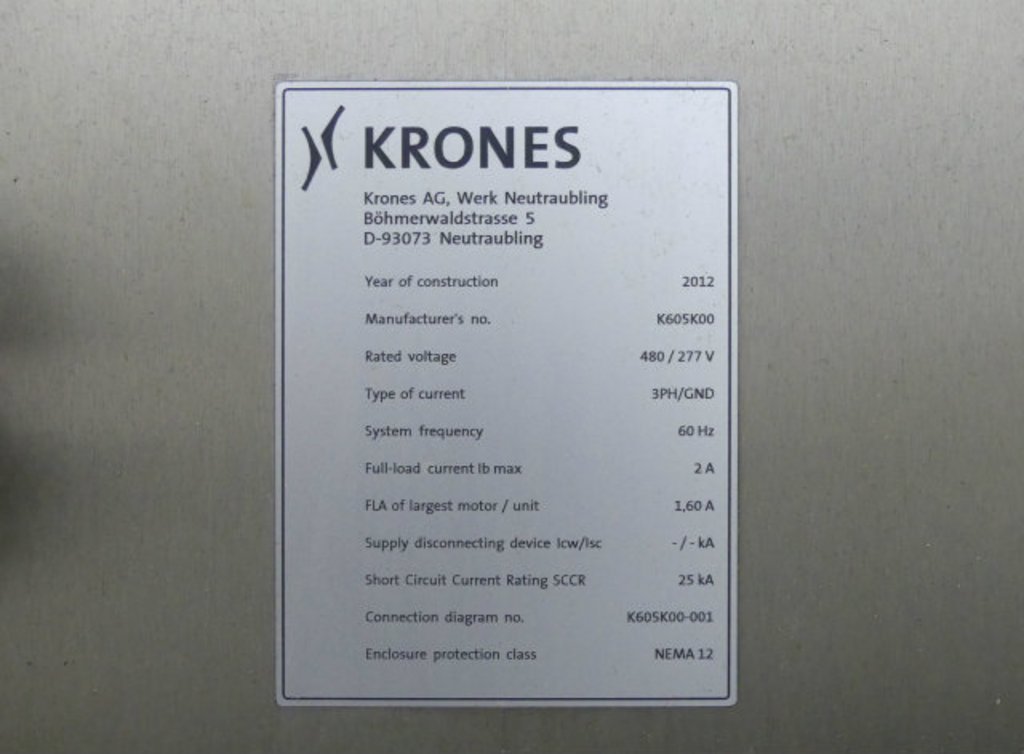

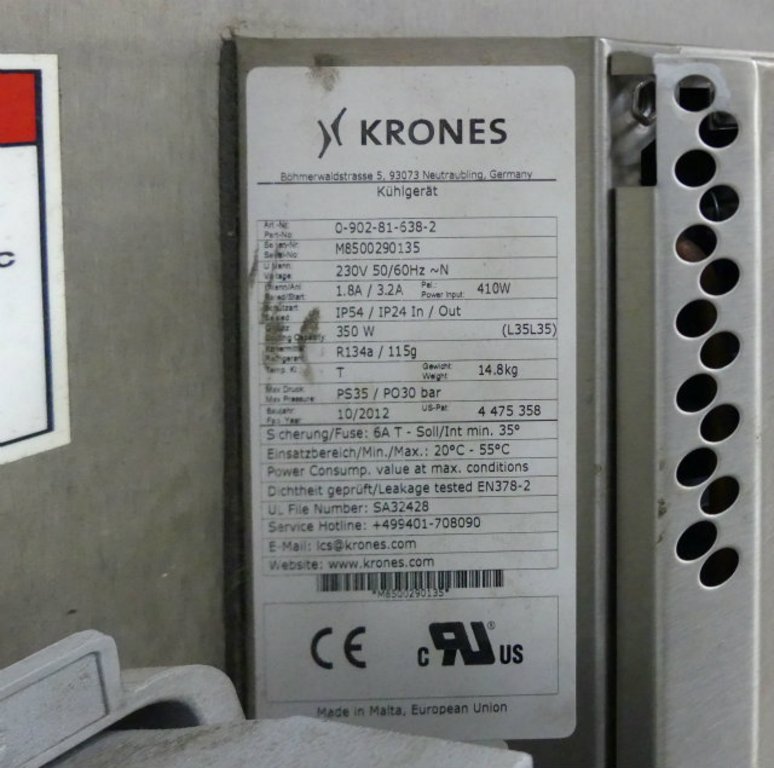

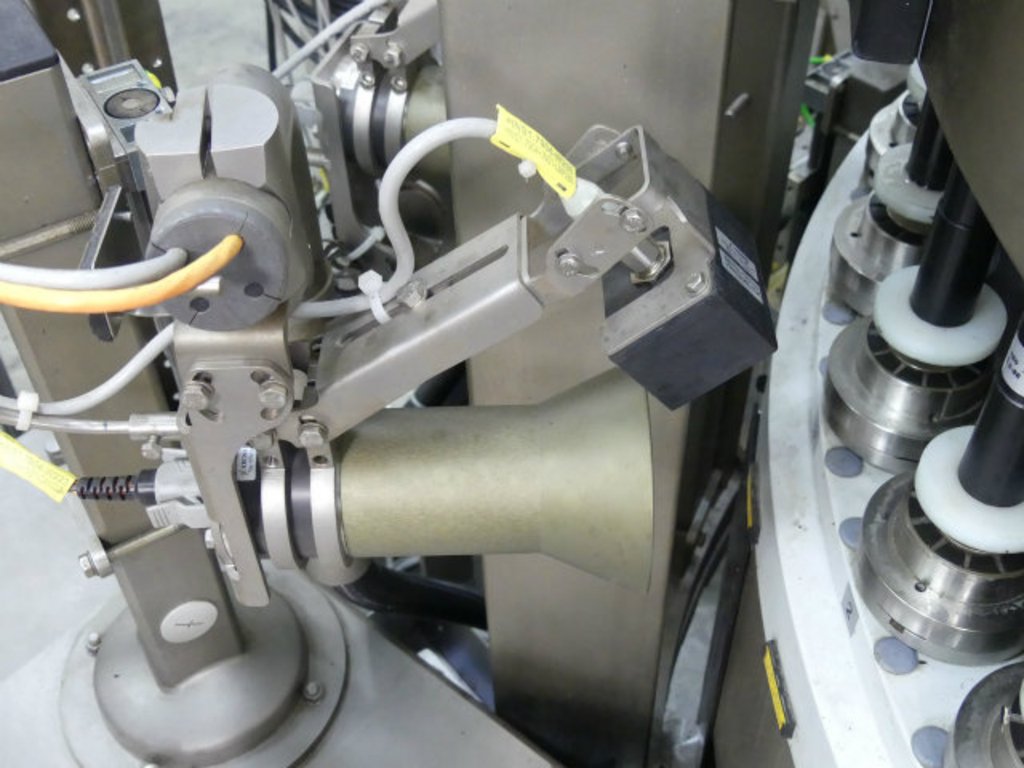

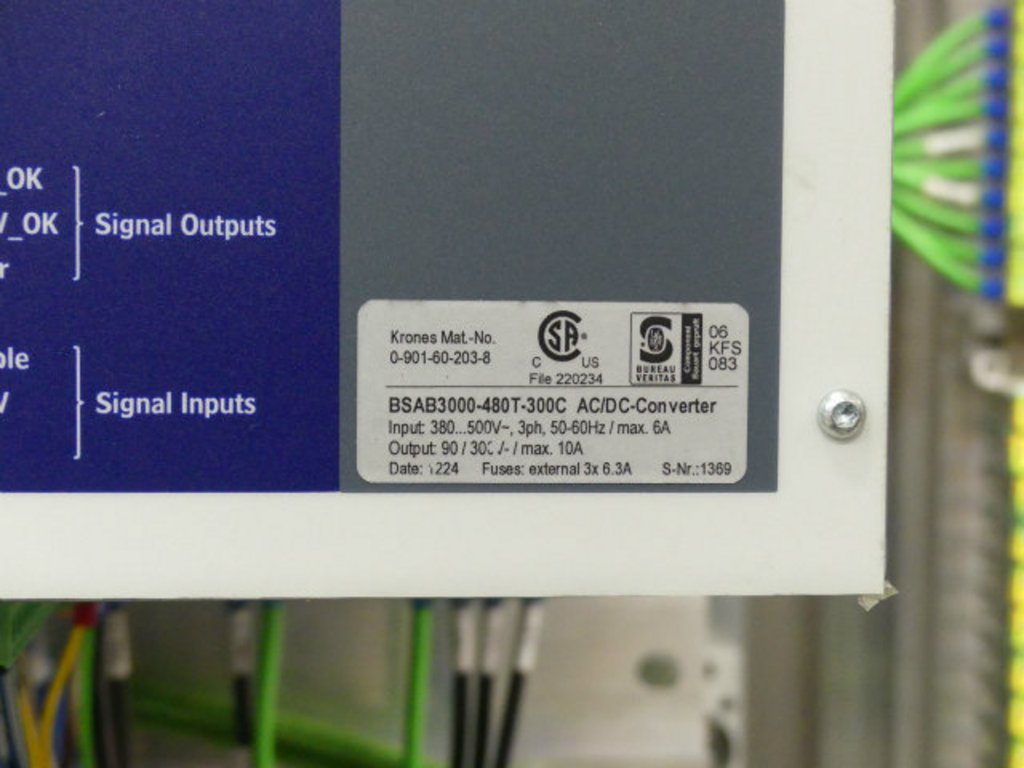

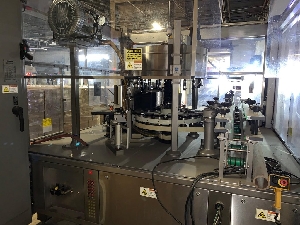

Used Krones SOLOMODUL II Glue Wrap Around Labeler with:

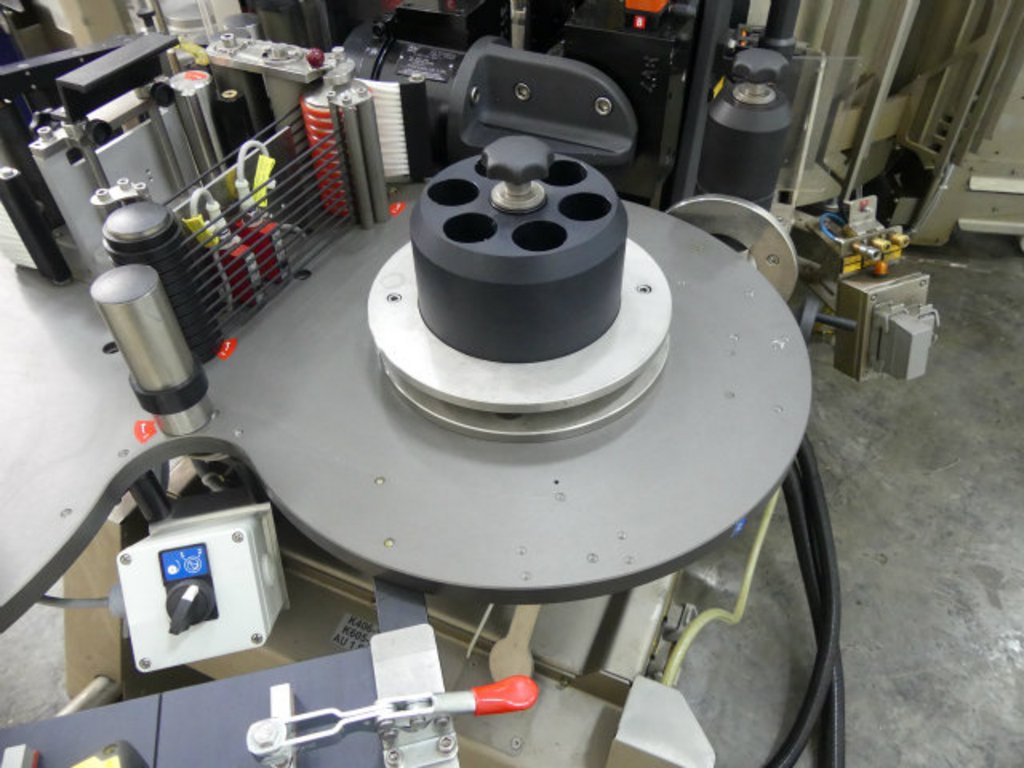

- Capable of labeling with both hot melt glue labels and pressure sensitive labels. Unit is sold with 4 aggregate heads. Two for hot melt glue and two heads for self adhesive labeling

- Krones modular labelers are multi-faceted, because they are suitable for labeling with cold-glue, hot-glue and self-adhesive labels just alike. The universal labeling machine is of modular design and can be configured from individual assemblies. The cold-glue and hot-melt labeling stations or the self-adhesive label applicators can be connected to the main machine as required. When changing the labeling process, the Plug & Label labeling stations can be replaced easily. It is also possible to use the cold-glue and self-adhesive labeling stations simultaneously or to change the labeling type after any time.

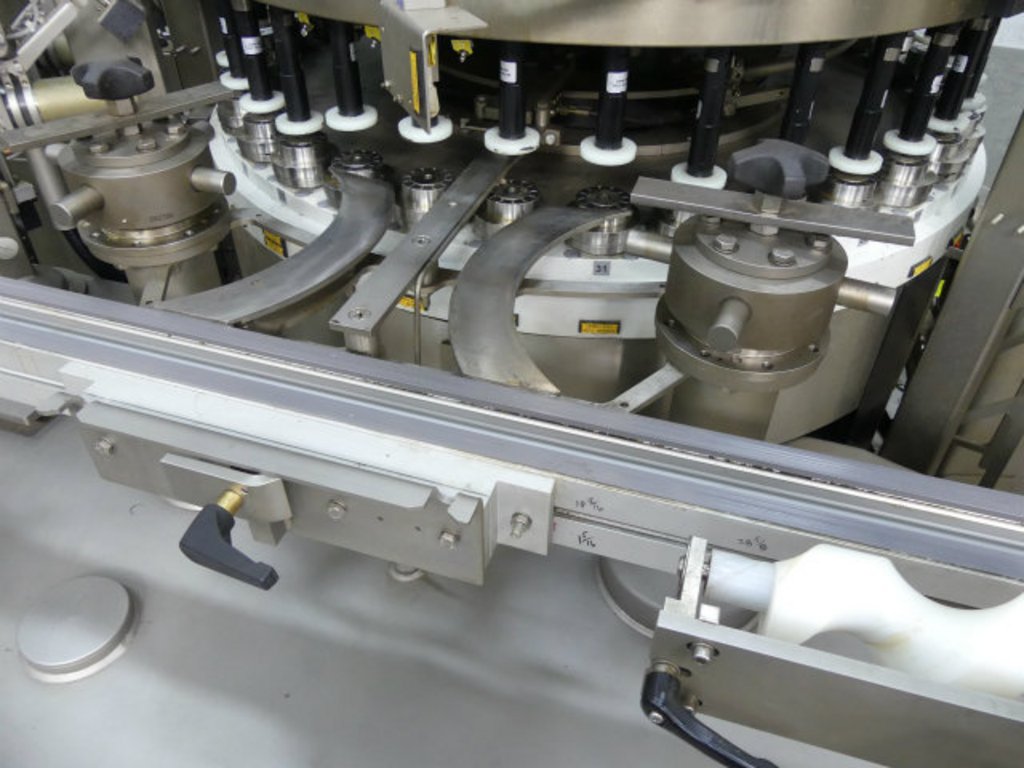

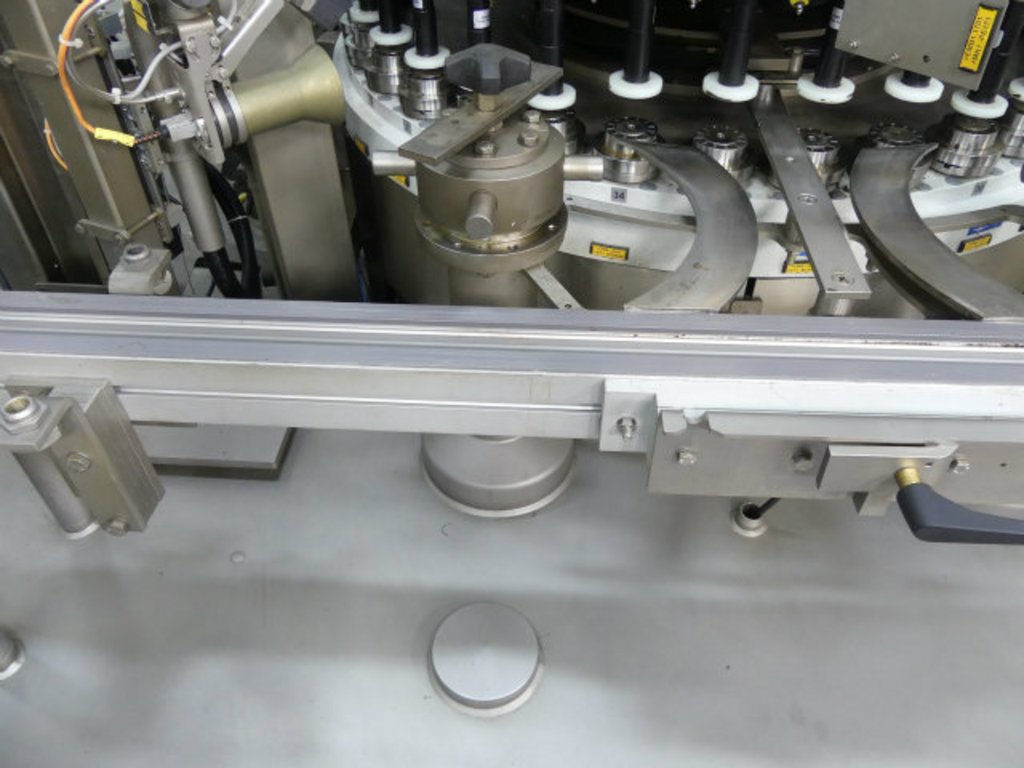

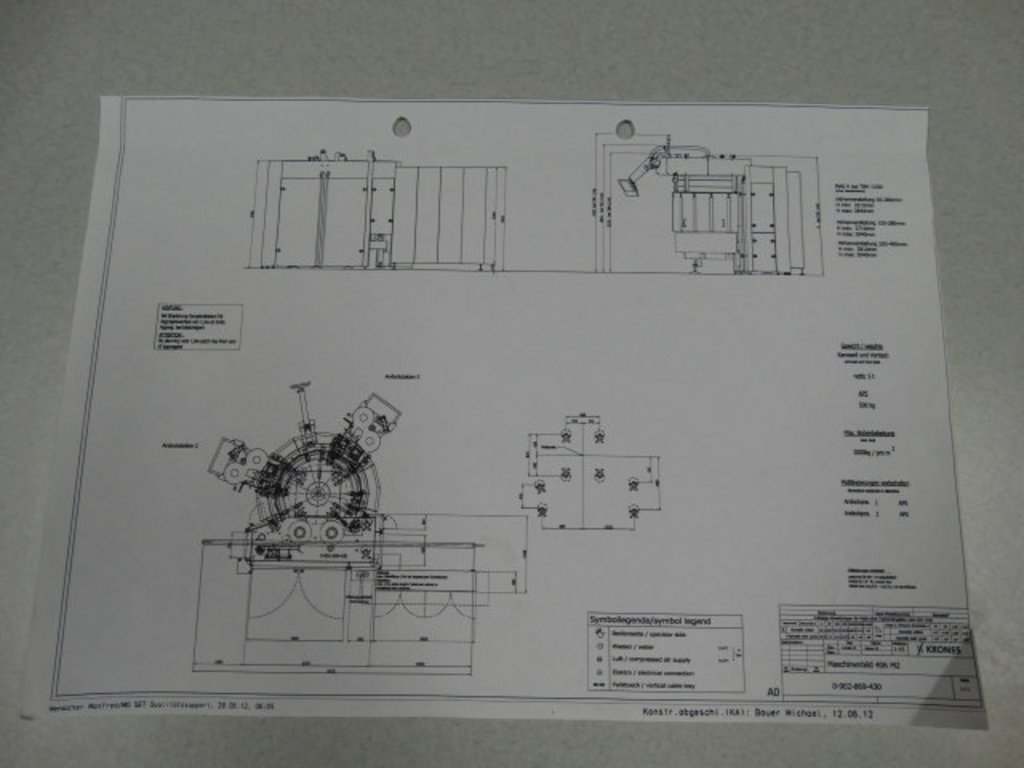

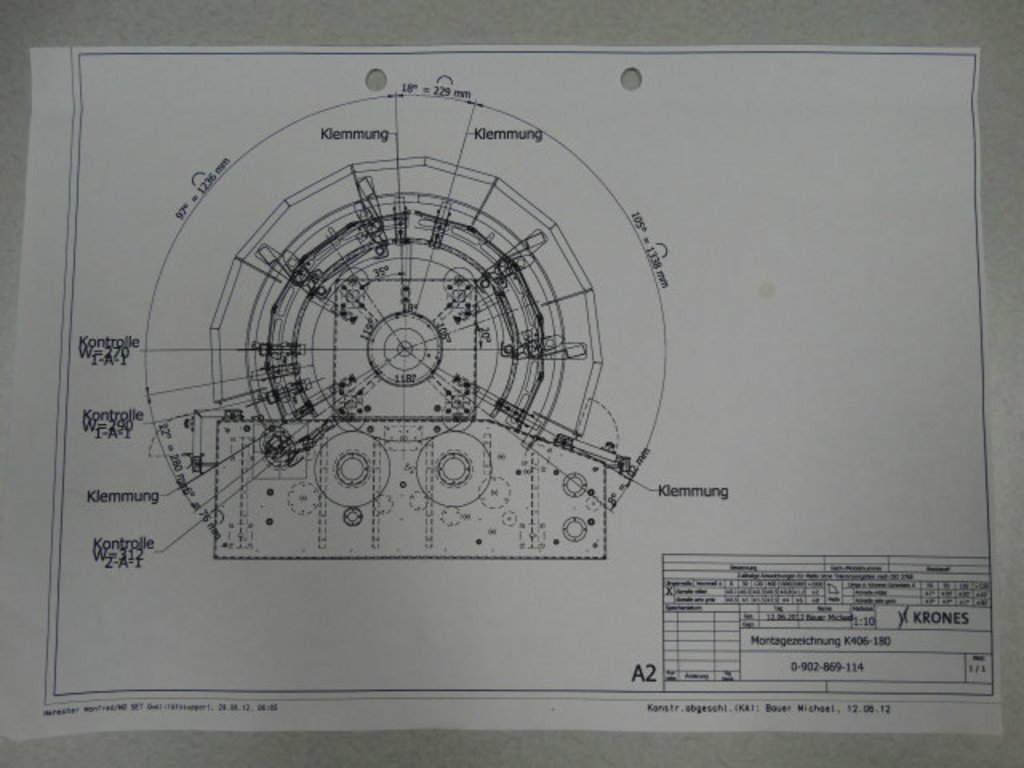

- Container carousel diameter: 1,200 millimeters

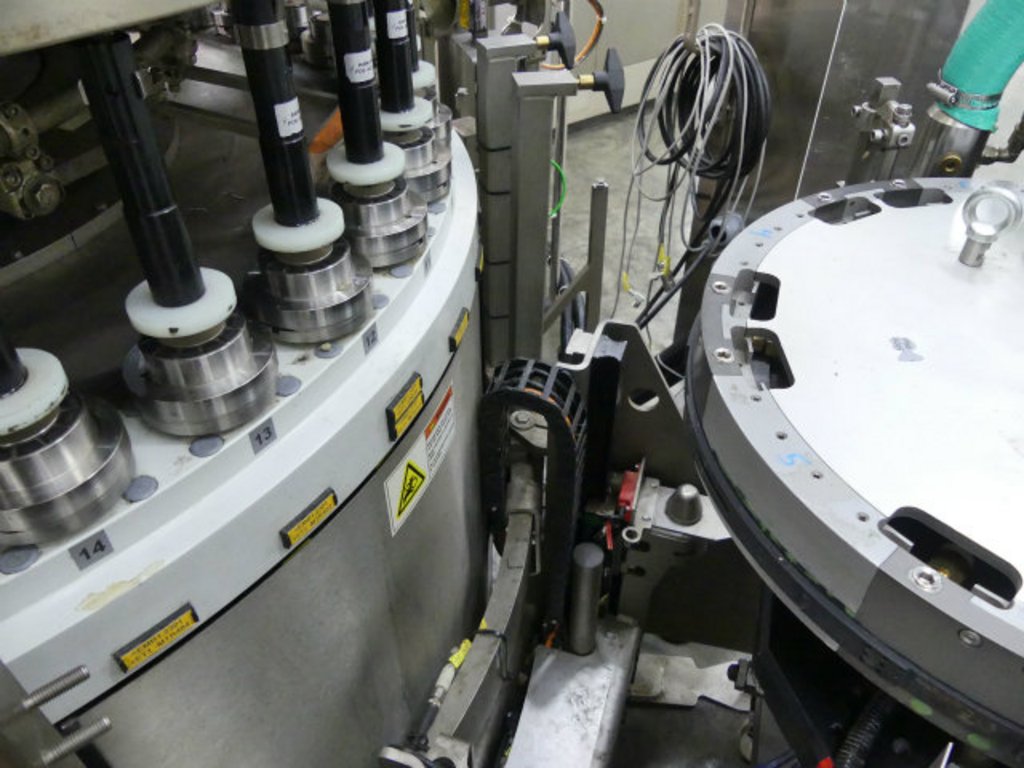

- Number of container plates (heads): 35

- Container plate centers: 107.7 millimeters

- Output range: depends on container dimensions and label type

- Minimum: 6,600 containers per hour

- Maximum: 28,000 containers per hour

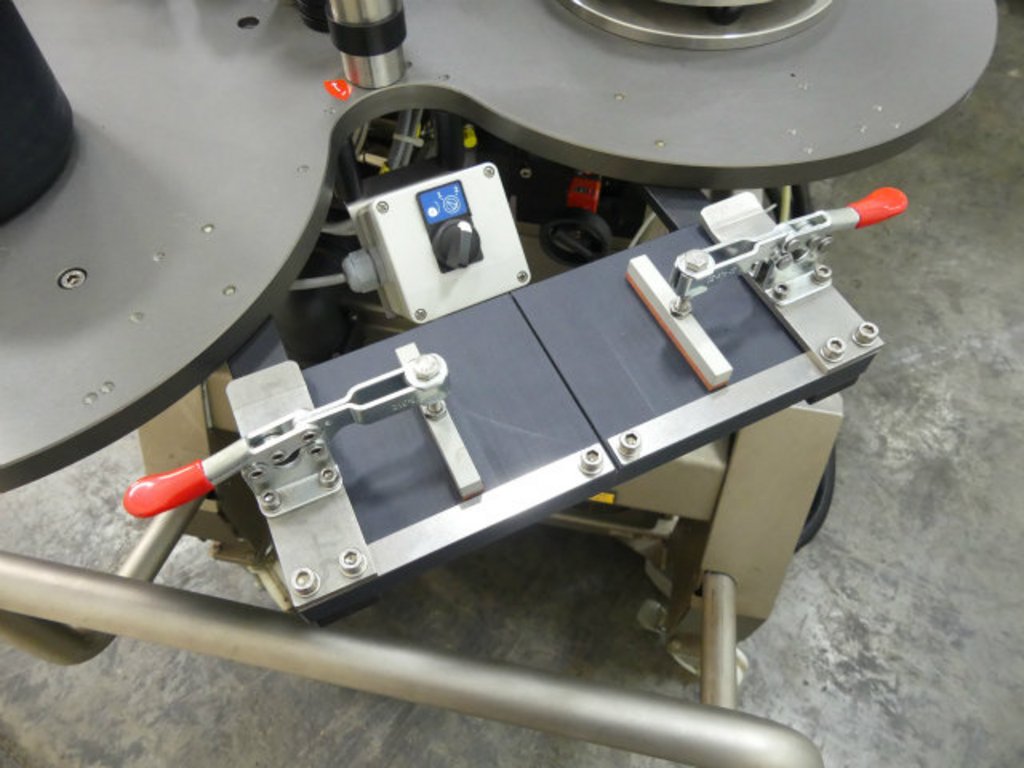

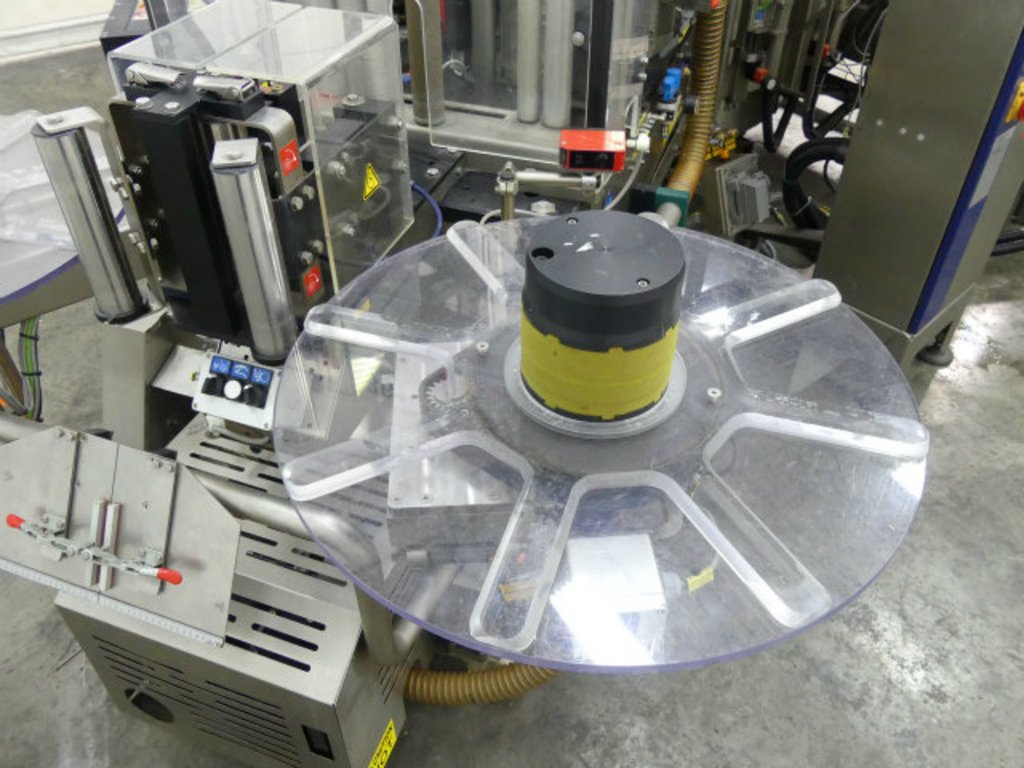

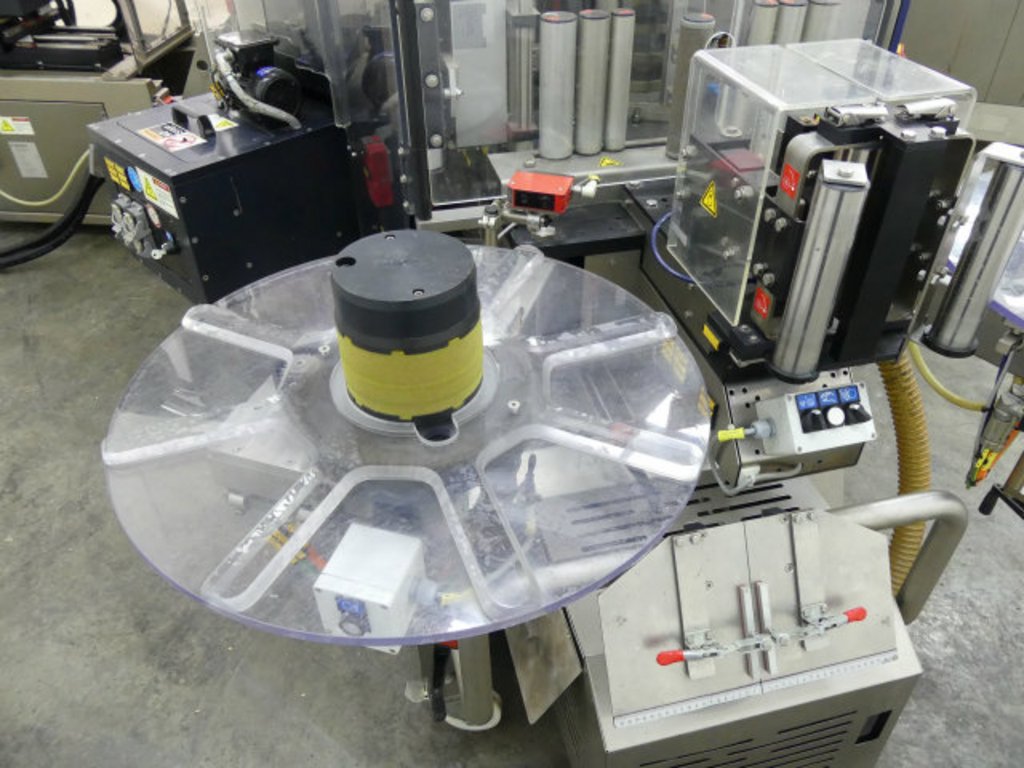

- Two APS 4 Plug and Label aggregates

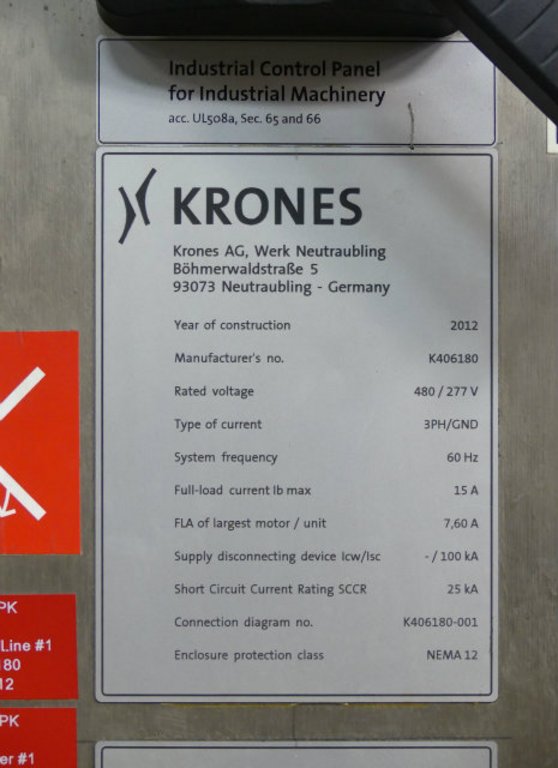

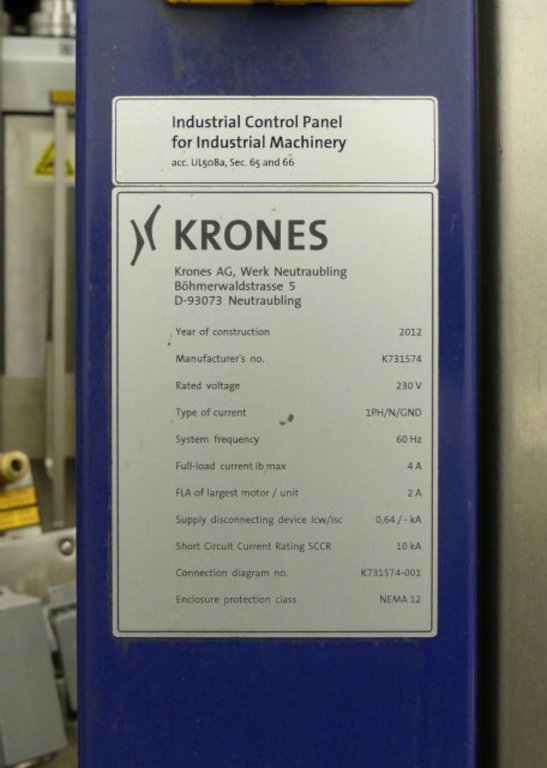

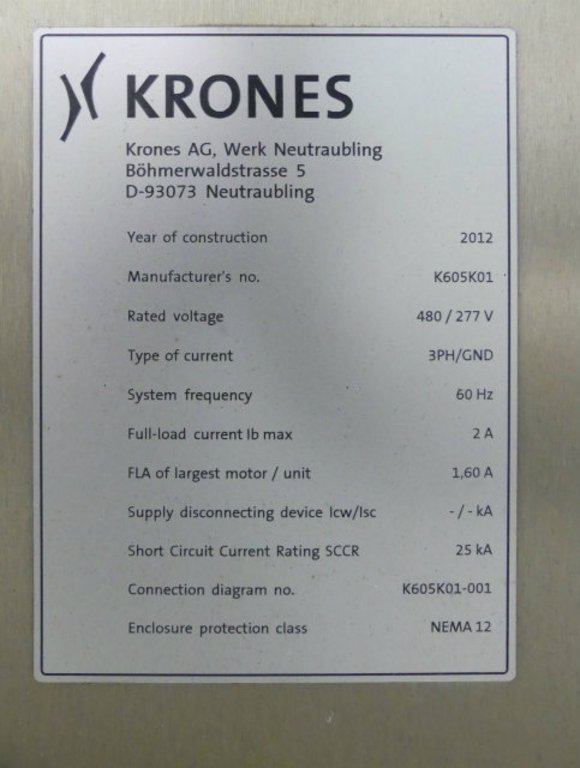

- Aggregate serial numbers: K605K00 and K605K01

- Precisely applies self-adhesive labels

- Output: up to 60,000 containers per hour, depending on container and label dimensions

- Label accuracy: +/- 0.2 millimeters

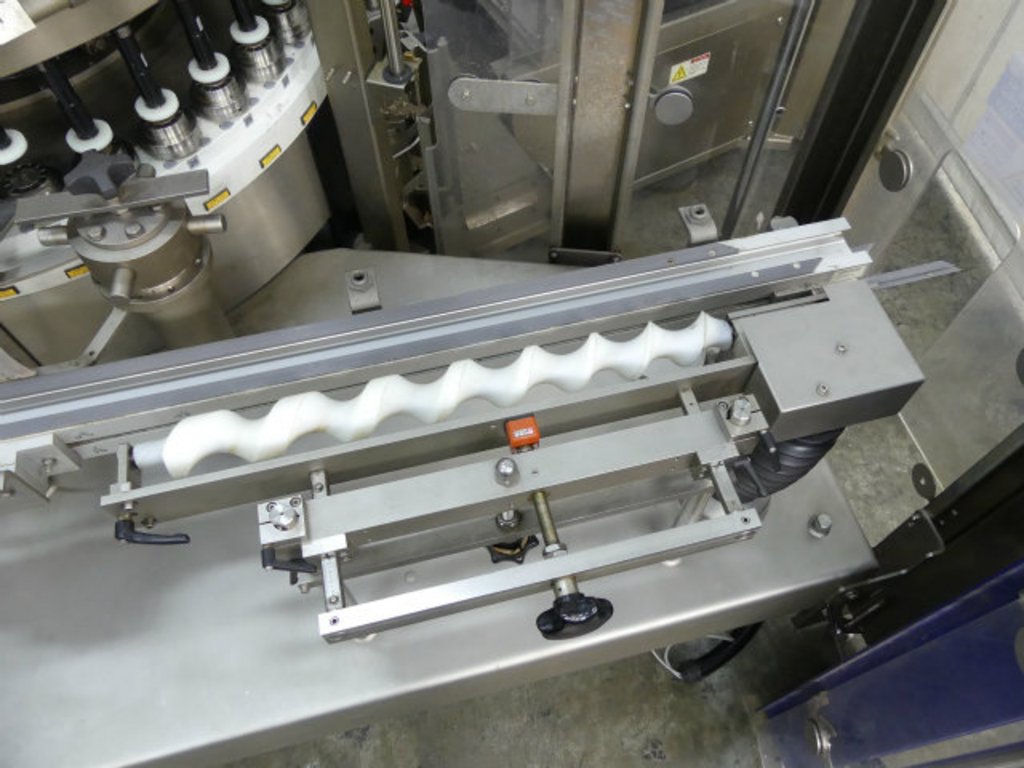

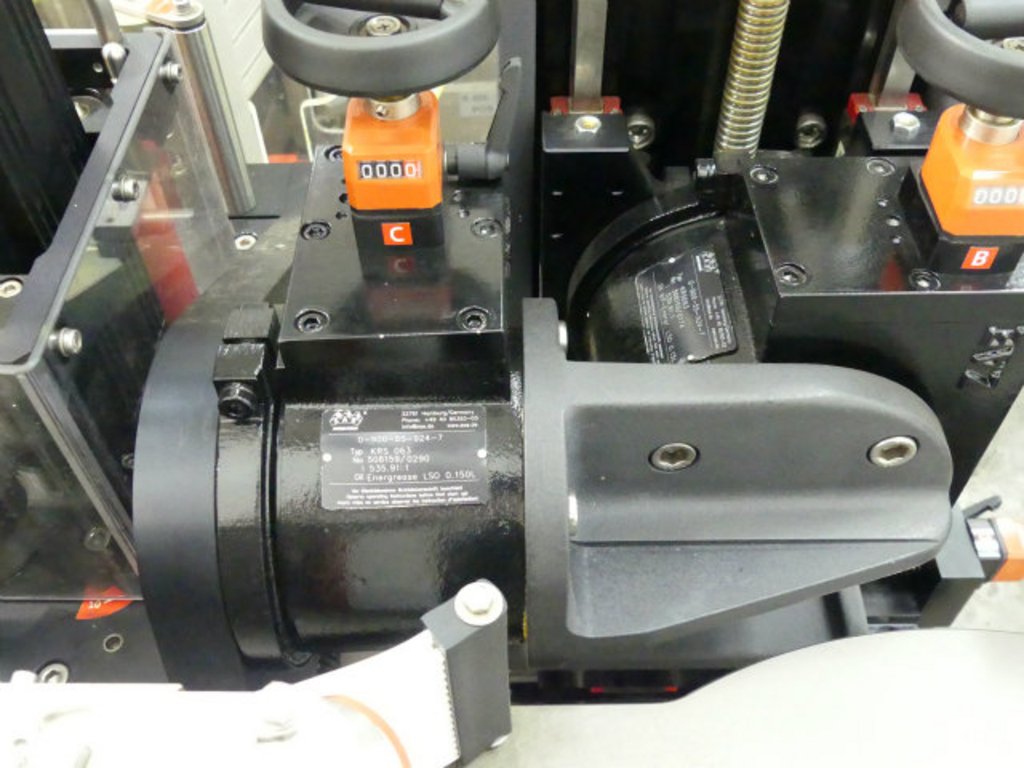

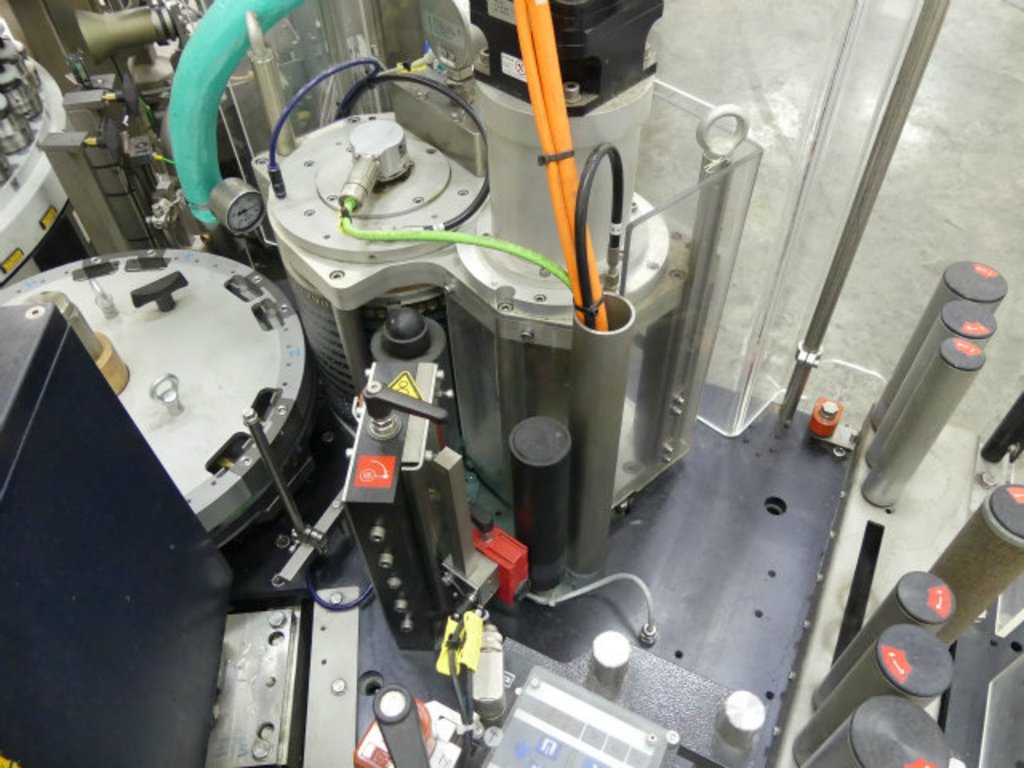

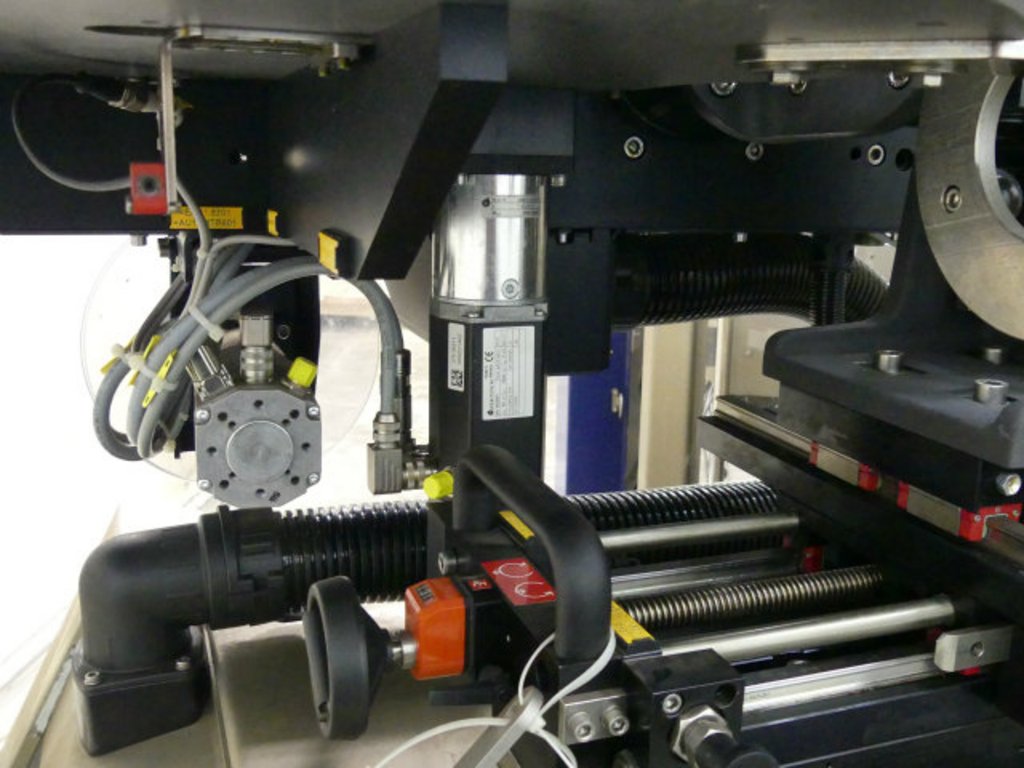

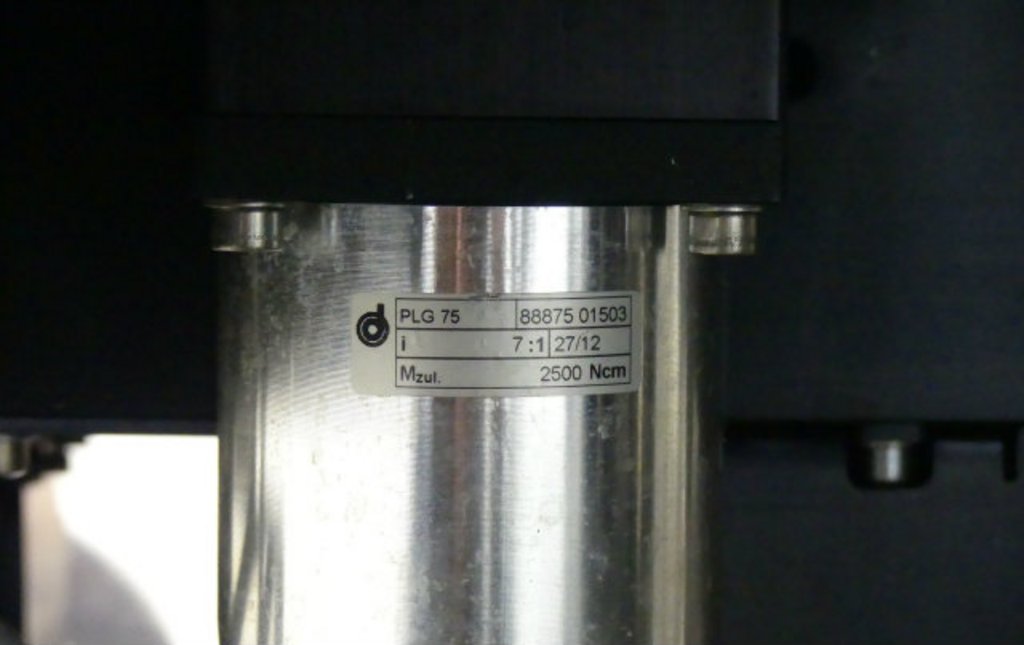

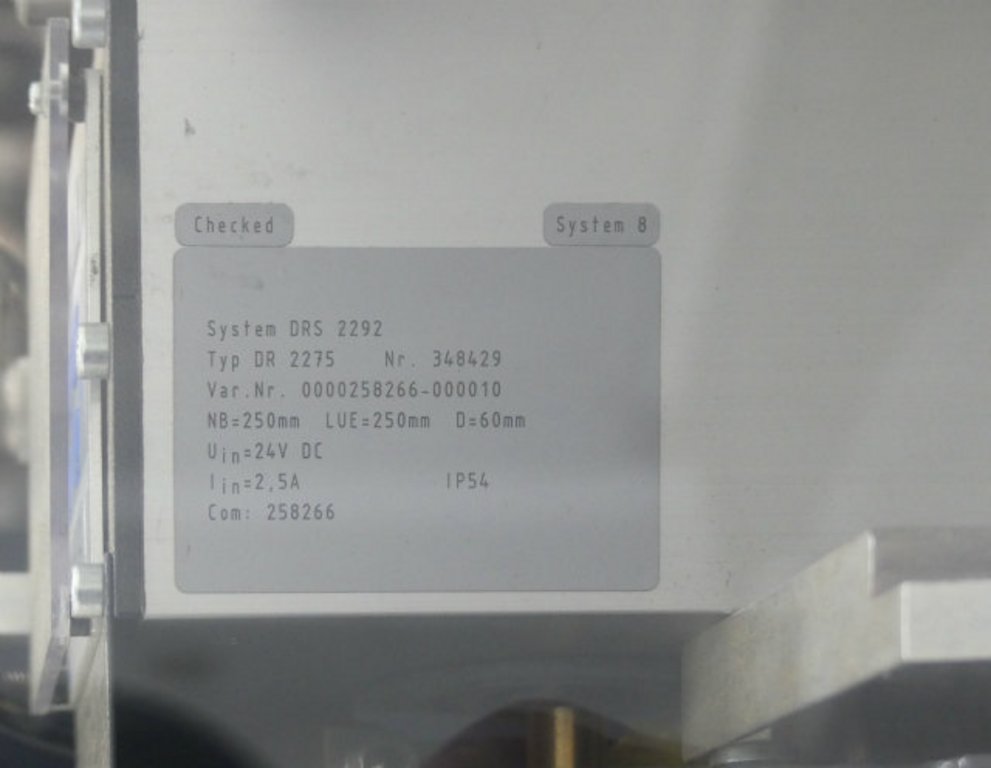

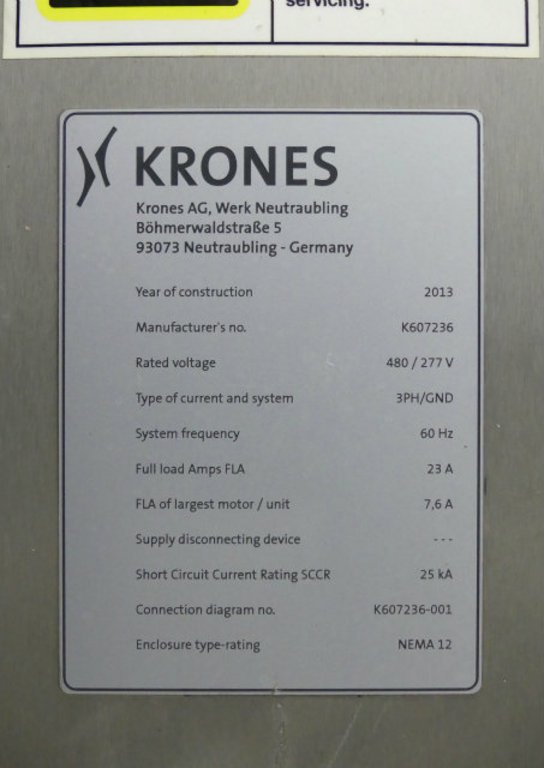

- Two Contiroll HS Plug and Label aggregates

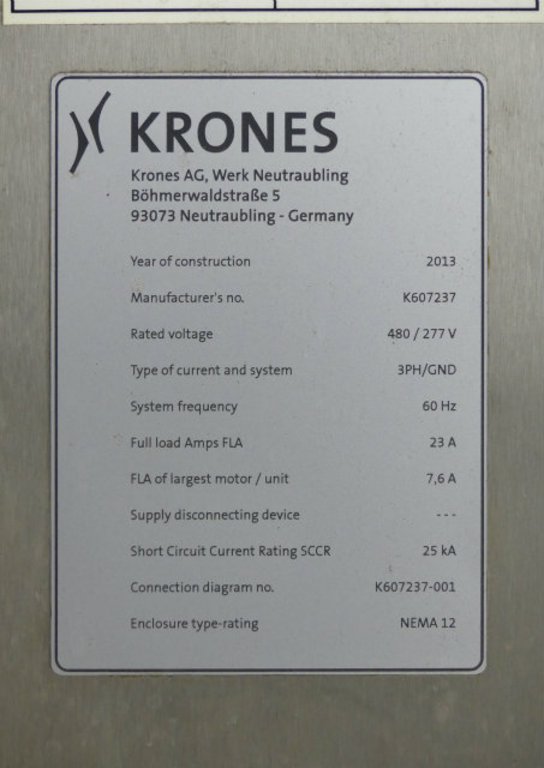

- Aggregate serial numbers: K607236 and K607237

- Precisely applies cut reel-fed wrap-around labels to containers

- Servo-motors drive the feed roller for the label web, the cutting unit, the vacuum-assisted gripper cylinder, the gluing unit, and the two reel holders

- Automatic label splicing

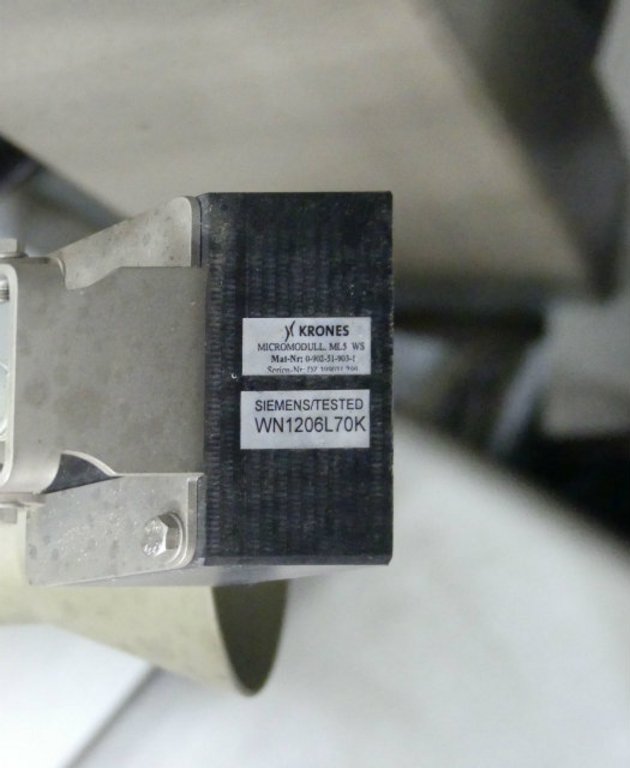

- Krones Checkmat vision inspection system

- Checks labels for proper fit and presence

- Checks the labels' position and angle of rotation

- Includes automatic reject system

- Independent servo driven container plates (heads) for maximum flexibility in any labeling scenario

- Right-to-left product flow, main turret rotates counter-clockwise

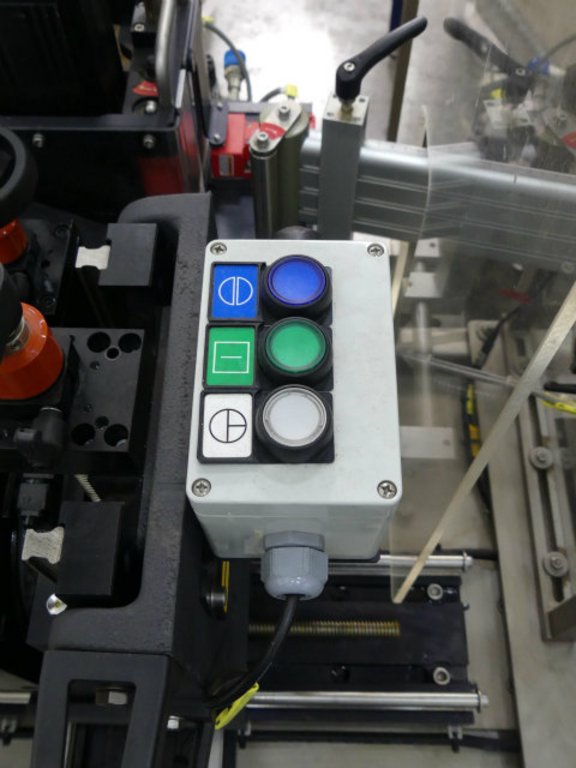

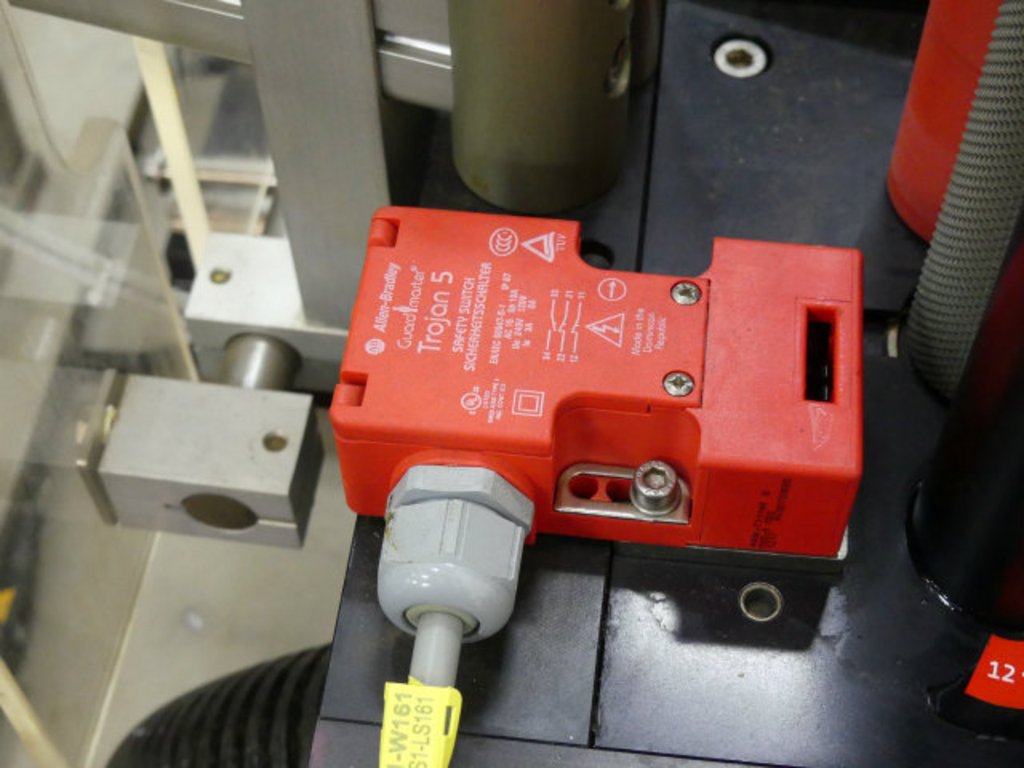

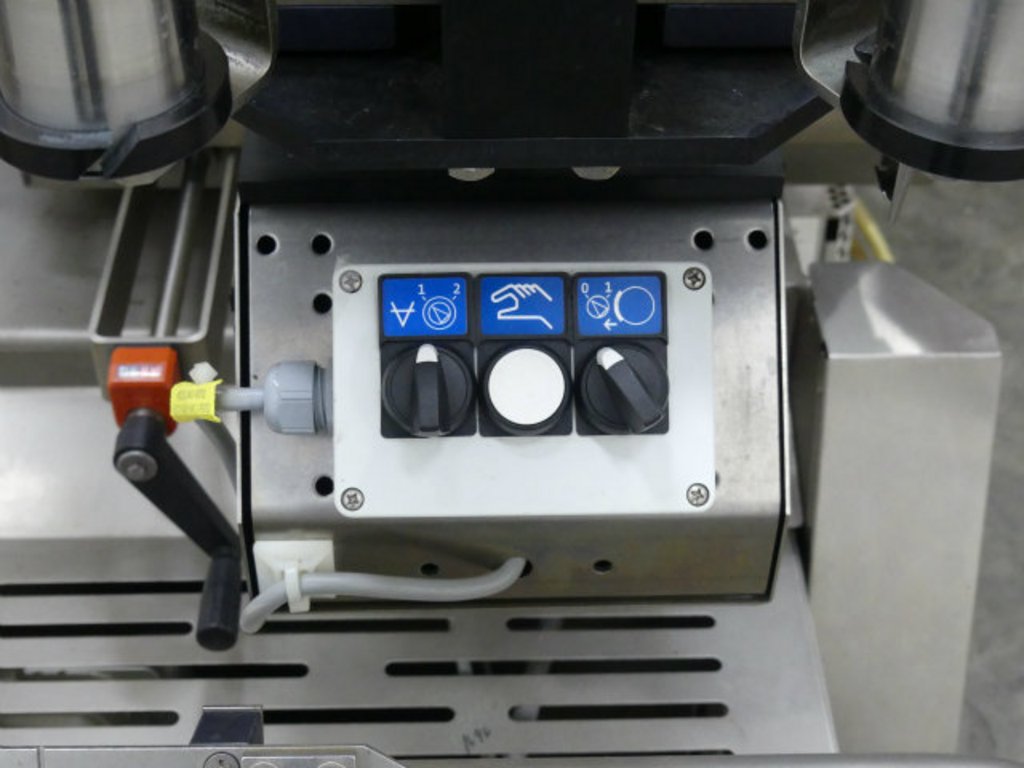

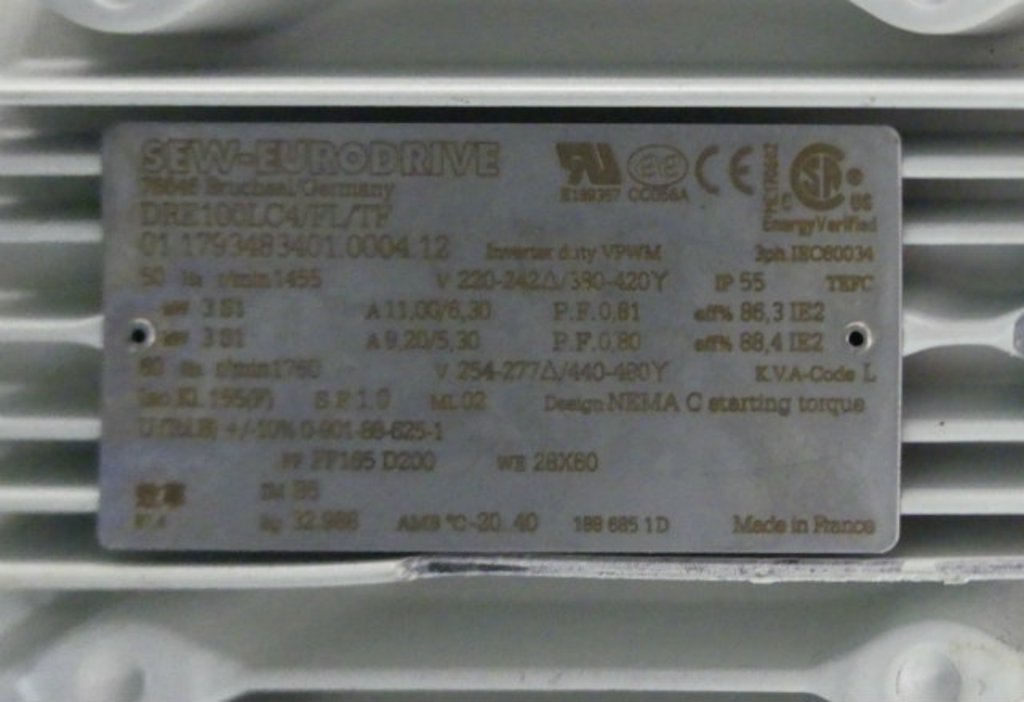

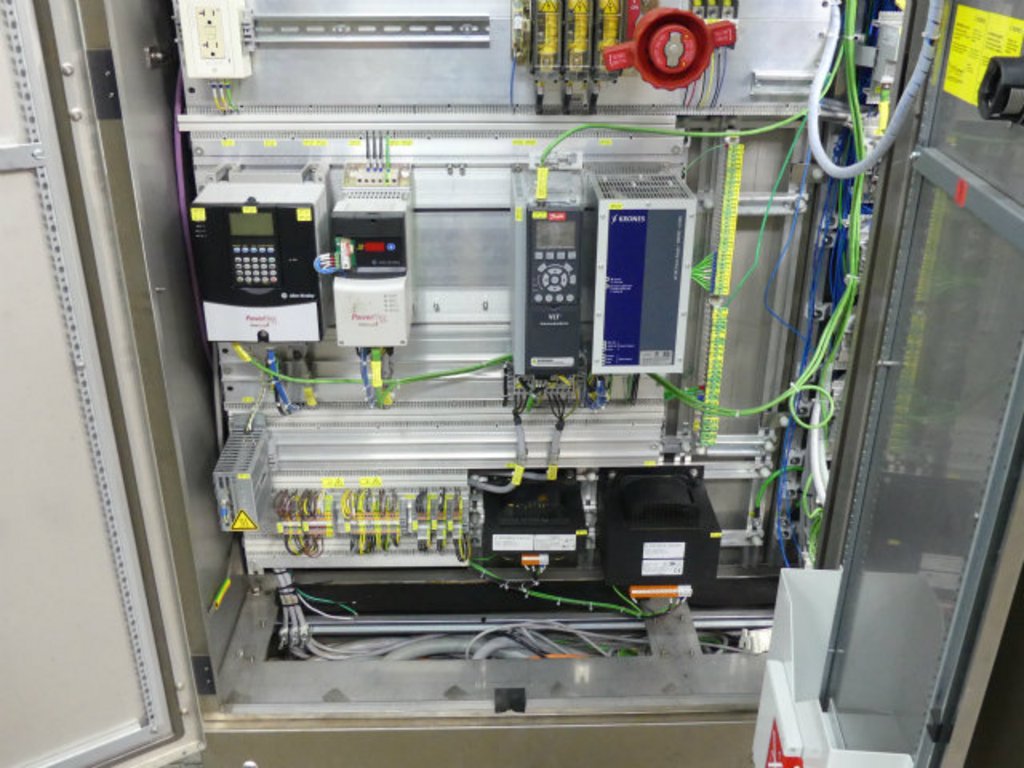

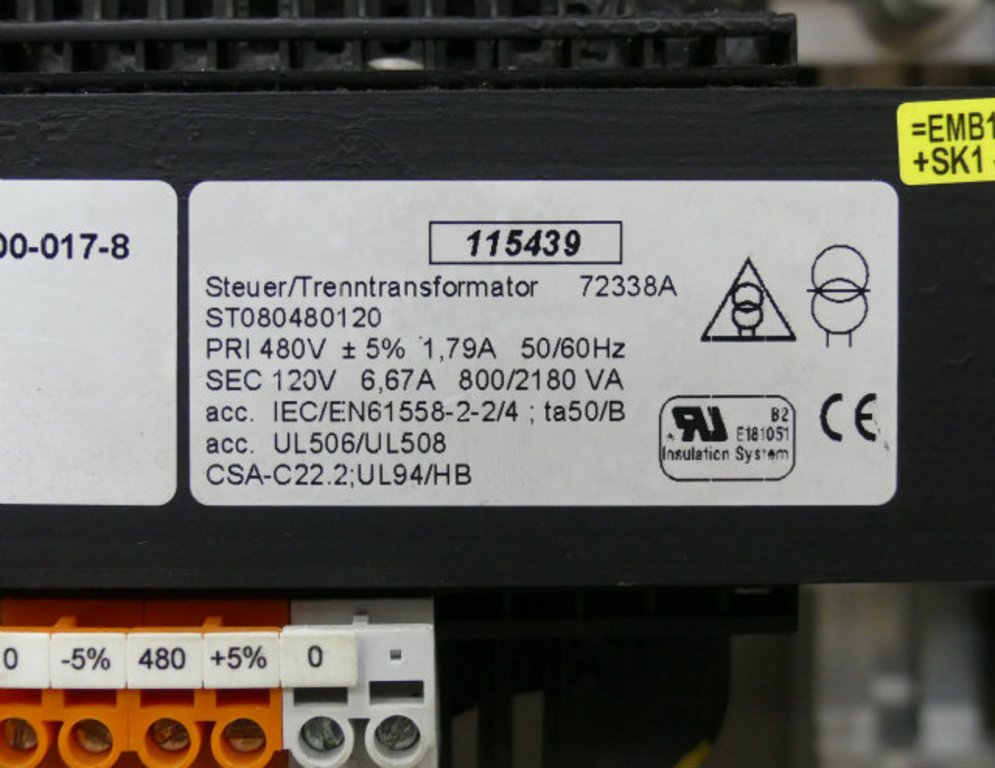

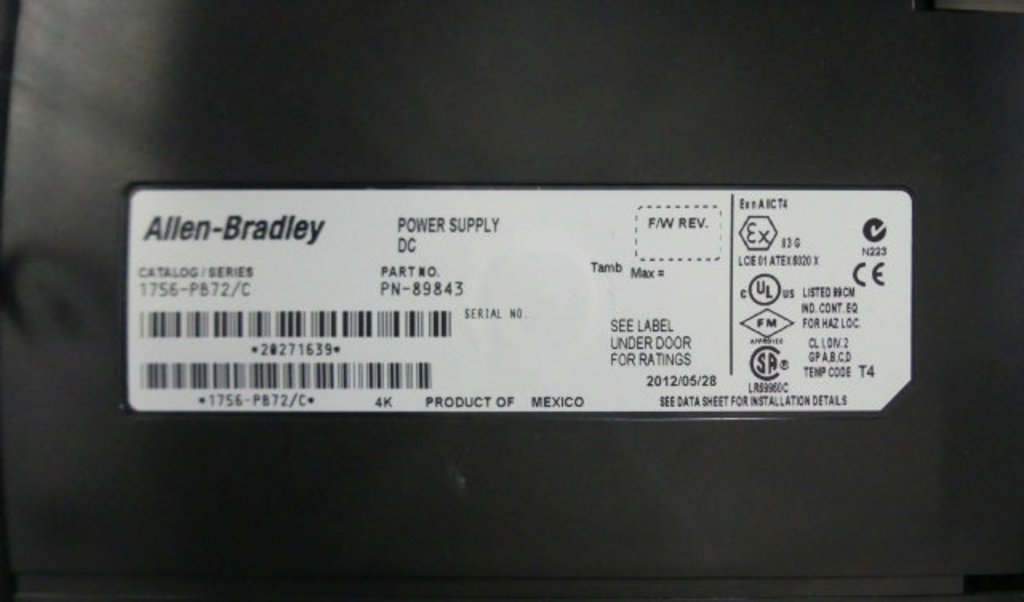

- Allen-Bradley Logix5562S controls

- Allen-Bradley PowerFlex70 and PowerFlex40 AC motor drives

- State of the art touchscreen HMI controller on swing arm

- Video container inspection option

- Capable of rotating container to specific container application location prior to applying labels

- Minimum and maximum label sizes to be confirmed by OEM

- Previously ran cans of smokeless tobacco

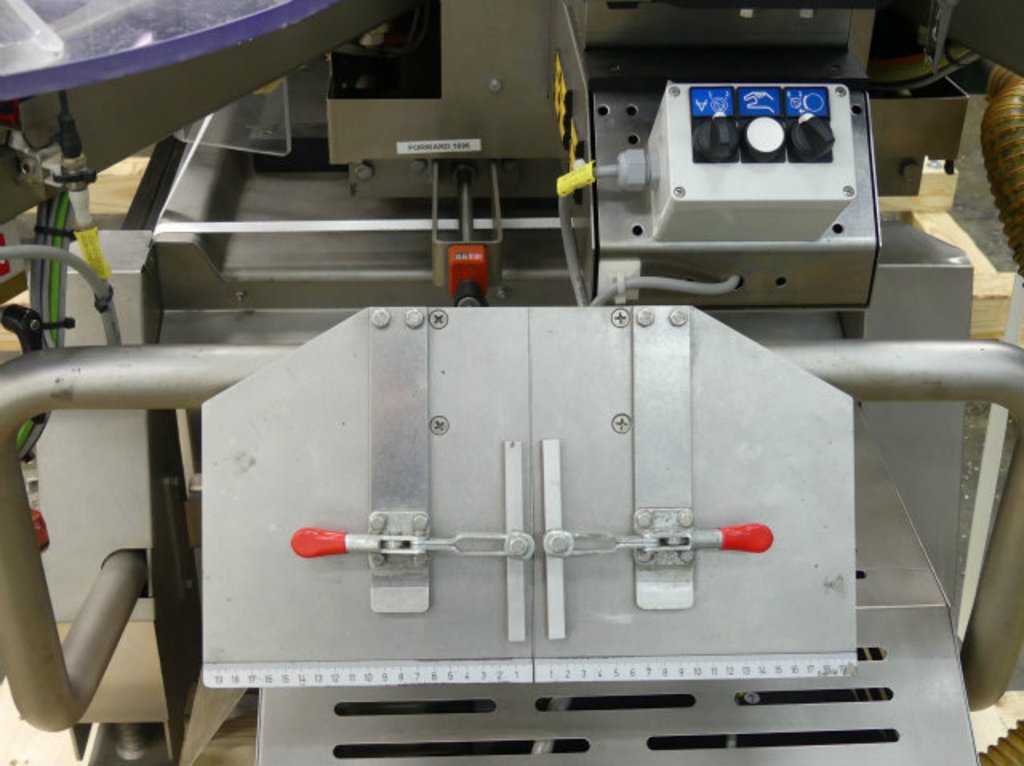

- Previously ran: 65 millimeter diameter x 23.5 millimeter tall cans

- Label dimensions: 19 millimeters tall x 210 millimeters long

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.