Description

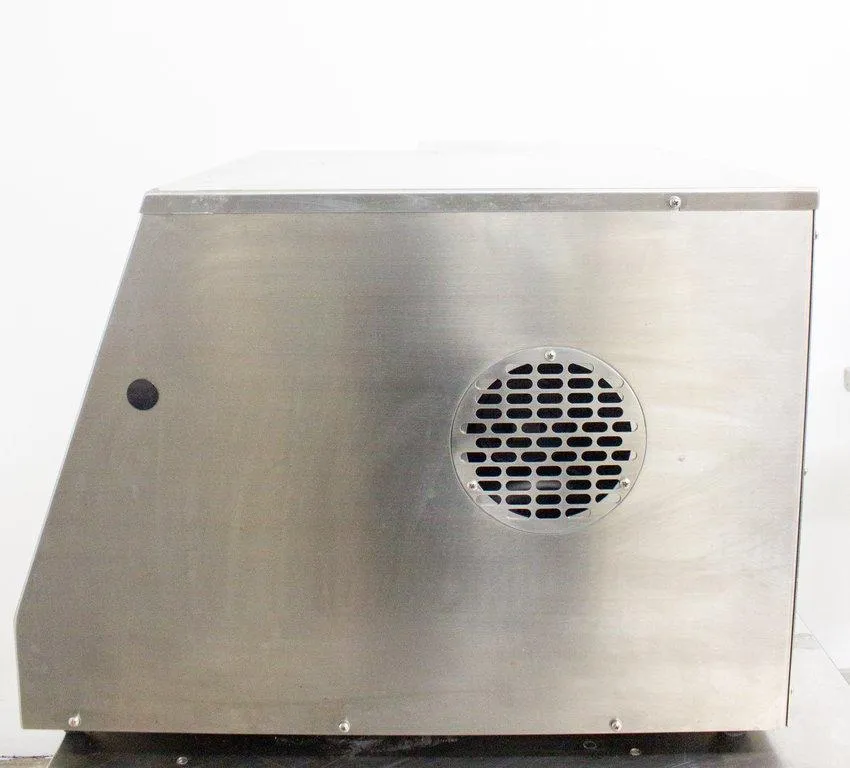

The Microfluidizer M110P processor is a lab-scale model that is a simple-to-use, electric benchtop fluid homogenizer. Using the Microfluidics fixed-geometry interaction chamber technology and a ceramic (Zirconia) plunger, the M110P is capable of successfully processing a wide variety of fluids, including oil-in-water emulsions, solids-in-liquid suspensions and performing cell disruption of yeasts and plant cells, much of which is performed with as few as one or two passes. The unit is powered by a standard 20-amp single-phase electrical outlet. The onboard 1.5 kW (2 HP) electric-hydraulic drive powers a single-acting intensifier pump. Process pressures are adjustable up to 2068 bar (30,000 psi) to produce the desired product results. No need for compressed air or hydraulic cooling water. This versatile laboratory homogenizer conveniently fits under most standard laboratory chemical hoods. This unit delivers a repeatable process with results that are guaranteed to scale up to pilot and production volumes.

- Operating pressure of up to 30,000 psi (2068 bar)

- Minimum sample size: 50 ml

- Flow rate: up to 120 ml per minute

- Product temperature limit: 158°F

- Recommended for:

- Production of stable nanodispersions and nanoemulsions

- Cell disruption (yeast, E. coli, etc.)

- Microencapsulation in polymers, liposomes & oils

- Deagglomeration

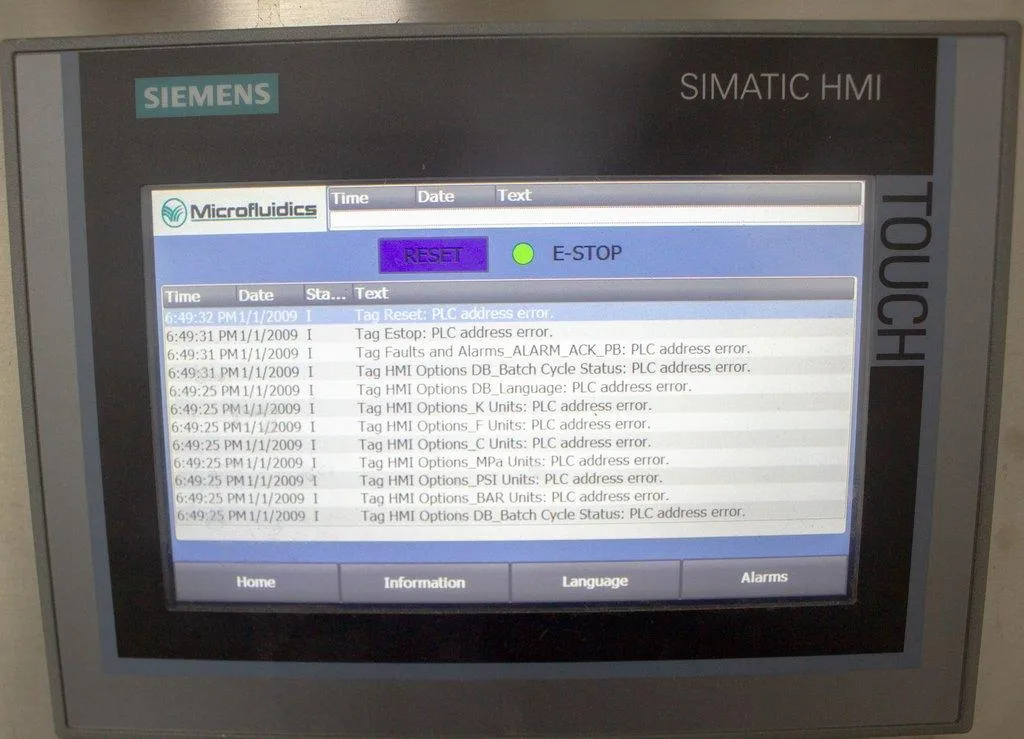

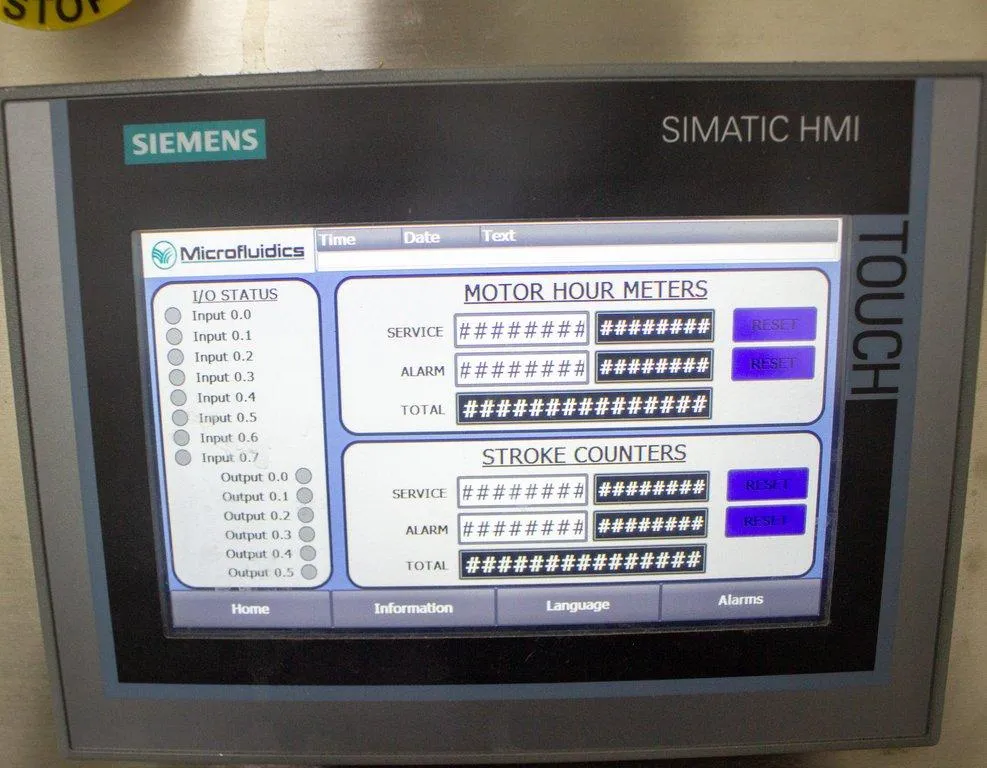

- Siemens touchscreen controls

- Electrical:

- Volts: 110

- Frequency: 60 Hz

- Phase 1

- Stainless steel construction

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.