Renewable Industrial Alcohol and Grain Processing Facility Call for availability

Videos

Click here for full page view of all Equipment Media (27)

Equipment Details

| Equipment # | E17464 |

| Item | Renewable Industrial Alcohol and Grain Processing Facility |

| Category | Turnkey Operation |

| Manufacturer |

Equipment Description

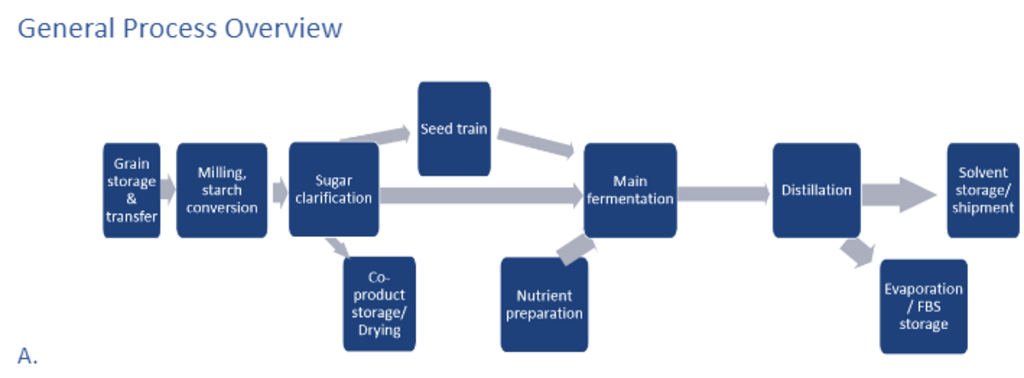

Renewable solvent/grain processing facility. Sterile process seed train and fermentation capable. Featuring 60,000 square feet between all the buildings. 27.23 acres over 3 parcels. Includes a full product testing and micro lab, scale house/grain receiving & storage, oil extraction system, milling, sugar clarification system, spent grain dryer and Laidig overhead feed storage/loadout. Also includes Aerobic Wastewater Treatment system, administration/office building with conference room, and a spare parts/chemical storage. Low capital entry for high protein feed products, renewable chemicals, industrial/GNS alcohol, butanol, acetone, isobutanol production systems.

- Building information:

- Number of buildings: 14

- 60,000 square feet from all buildings

- Located on 27 acres

- Utilities:

- City water

- City sewer

- Electricity and natural gas

- Storm water retention pond

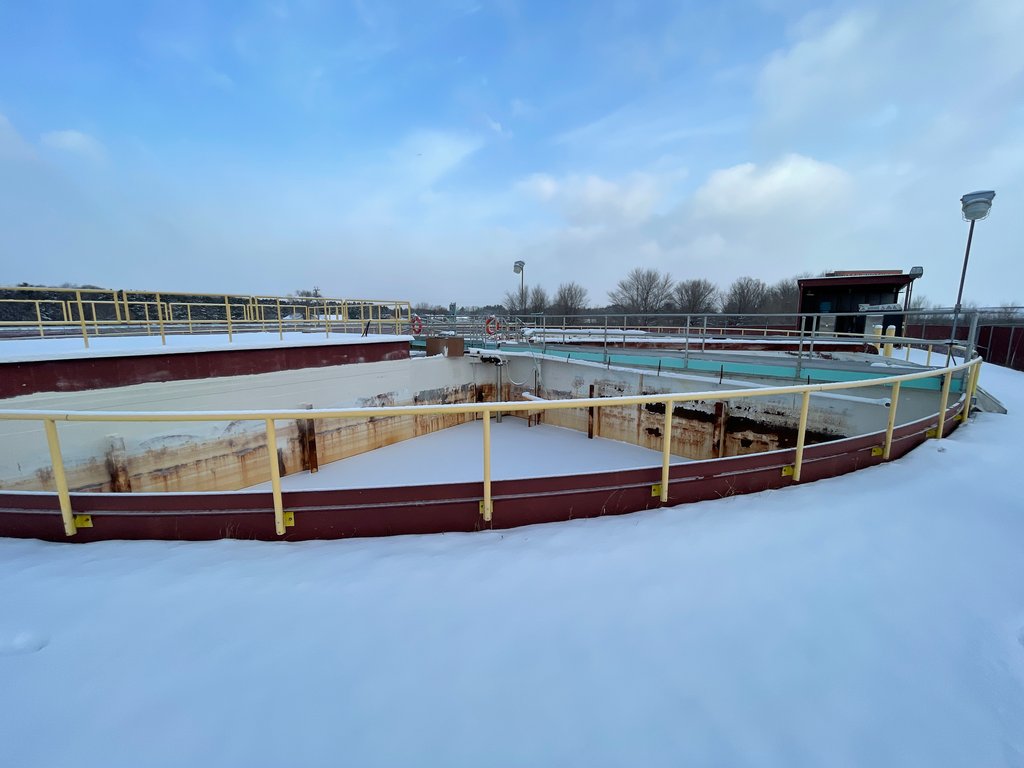

- Aerobic wastewater treatment facility

- Operations:

- Grain Handling:

- 3 grain silos

- 20,000 bushels

- 80,000 bushels

- 250,000 bushels

- Blending system]

- Running 1500 bushels per hour

- 3 grain silos

- Milling and Conversion:

- Hammermills (2)- 1000 Bu/hr. 250HP

- Ribbon blender

- Slurry Tank: 17000 gallons

- Jet cooker

- Cooker tank: 4000 gallons

- Liquefication tanks:

- 18,000 gallons

- 33,000 gallons

- Saccharification tank: 121,000 gallons

- Enzyme tank: 7000 gallons

- Rates:

- Grind and jet cook: Approximately 1,000 bushels/hour, approximately 38 percent solids

- Peak annual usage approximately 7.2 million bushels

- Corn Separations:

- Rates:

- approximately 350 gallons per minute at approximately 38 percent solids

- Rates:

- Nutrients and Additives:

- Aqueous ammonia tank and containment: 11000 gallons

- Nutrient storage tanks:

- 7,500 gallons

- (2) oil tanks: 7,000 gallons each

- Bulk bag unloader with 50 pound dump station

- Nutrient mix tank: 2,000 gallons

- Sulfuric acid: 4500 gallons

- Clarified sugar distribution:

- 121000 gallons

- 300 gallons per minute

- Rates:

- Ammonia: 5 gallons per minute

- Nutrient sterilizer: 25 gallons per minute

- Water sterilizer: 250 gallons per minute

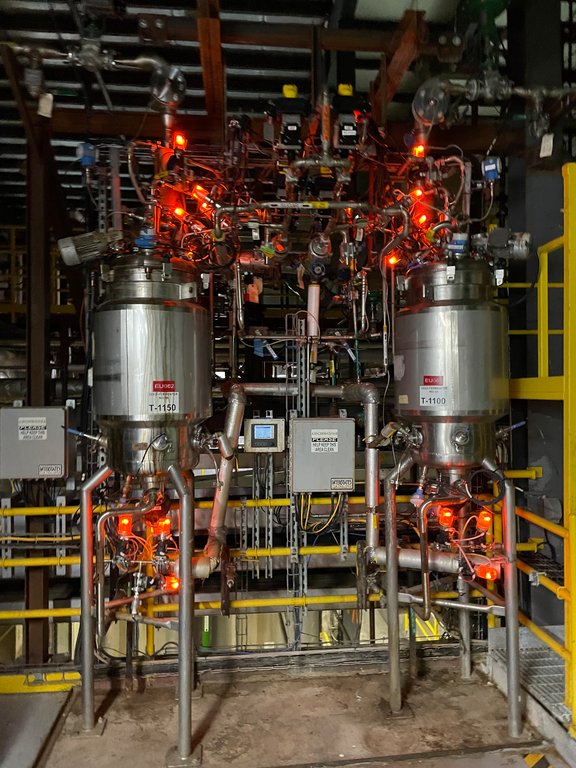

- Seed Cultures:

- Seed Fermenters:

- (2) 44 gallons

- (2) 2,000 gallons

- (1) 28,500

- Seed Fermenters:

- Fermentation:

- (4) stainless fermenters: 285,000 gallons

- CIP Systems

- Fermentation Broth Handling:

- (10) Alfa Laval Ultra Filtration skids

- (1) Alfa Laval CIP skid

- Rates:

- Up to 2000 gallons per minute dependent on filter elements

- Distillation:

- Dilute stripping tower

- Beer stripper: 130 gallons per minute

- CIP system

- Solvent Purification towers & treatment

- Molecular sieve

- Evaporation of stillage:

- Operated at 120 gallons per minute at less than 10 percent solids and achieved 35 percent solids

- Animal Feed Dryer:

- Drum dryer: natural gas burner

- Cooling drum

- Bulk dry bins

- Rates:

- 8000 therms of natural gas per day

- 7 tons per hour dry output (14 percent moisture) with 65 percent moisture on feed

- Product Tank Farm and Load Out:

- Acetone Storage Tank: 28000 gallons-SS

- Acetone Shift Tank: 3500 gallons-SS

- Acetone Shift Tank: 3500 gallons-SS

- Butanol Shift Tank: 30000 gallons-CS

- Butanol Shift Tank: 30000 gallons-CS

- Butanol Final Product Tank: 185000 gallons-CS

- Ethanol Storage Tank: 15000 gallons-CS

- Off Spec Tank: 30000 gallons-CS

- Warehouse and Other Equipment:

- Boilers:

- 34500 pounds of steam per hour

- 28000 pounds of steam per hour

- Cooling towers

- 37.5 million btu per hour per cell-2cell

- 7500 gpm per cell with circulation pumps

- Chillers

- Air compressors

- Reverse osmosis skids

- Boilers:

- Analytical Laboratory

- (2) Ultimate HPLC-RID systems

- (5) GC-FID systems

- Anton Paar-Bench Densitometer

- Anton Paar-Automatic Distillation Unit

- Anton Paar-Flash Point Tester

- MT Coulometric KF

- (2) MT Auto titrators

- Auto-pipettes

- Distillation apparatus

- Microscopy station

- Multiple Moisture Balances

- Multiple Analytical Balances

- Microbiology Laboratory

- Laminar Flow Hood

- Media prep station

- Microscopy Station

- (2) Amsco/Steris Model 3043: Pre-vac sterilizers

- Multiple Incubators/Shakers

- Full Lab RO system/Dishwasher

- Dedicated Glassware & Carboy Inventory

- Lab Centrifuges-J6M & multiple bench top/microtube units

- Grain Handling:

Location Details:

North Central USThis machine is located at a client’s facility in North Central US. To coordinate an inspection of this item, please contact your SIGMA sales team.

Call us at (812) 303-8383.Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this Renewable Industrial Alcohol and Grain Processing Facility?

Request an email quote or call us at (812) 303-8383 for more information.