A Guide to Bulk Plastic Bottle Unscramblers

Helping You Unscramble Your Production Line

Topics we will cover:

- What is a bulk plastic bottle unscrambler

- Benefits of an unscrambler

- What industries use an unscrambler

- What types of bottles are used

- Where are they located in production

What is a Bulk Plastic Bottle Unscrambler?

A bulk plastic bottle unscrambler will orient, process, and position large amounts of plastic bottles into the production so they are prepared for further downstream processing.

These unscramblers can handle a range of various bottling sizes, including:

- Lightweight bottles

- Heavyweight bottles

- Cylindrical bottles

- Oval or asymmetric bottles,

- Flat elements like cream jars

The bulk plastic bottle unscrambler can also handle bottles with or without labels or decorations already applied. This means the unscrambler can be placed in a variety of locations within your production for pre or post-filling. These machines are great for mid-level manufacturing companies who want to improve their automation and streamline production.

Benefits of a Bulk Plastic Bottle Unscrambler:

1. Reduces Manpower

Incorporating a bulk plastic bottle unscrambler into your production will automate the packaging process so that you don’t need a worker overseeing operations. This will allow you to put that energy elsewhere within your facility, saving you time and resources.

2. Increases Employee Safety

Since the bottling handling is automated and is being done by machine, there leaves no room for human error. You can be assured that all bottles will be handled with the utmost safety and cleanliness which will have you from products being spoiled.

As you consider your growth and future plans for production, a bulk plastic bottle unscrambler is a piece of equipment that can grow with you.

Top Industries used:

The industries that might use a bottle and scrambler are:

- Cosmetics products like liquid make up, face creams, moisturizers, and hair care

- Pharmaceutical products including vitamin bottles and medicine supplements

- Food products such as spices, sauces, and seasonings

- Household products such as cleaners, liquid soaps, and hand sanitizers

It’s important to note that typically, the beverage industry uses preform blown plastic bottles that are incorporated at the beginning of the production line. This removes the need for a bulk plastic bottle unscrambler.

Where it fits in a production line:

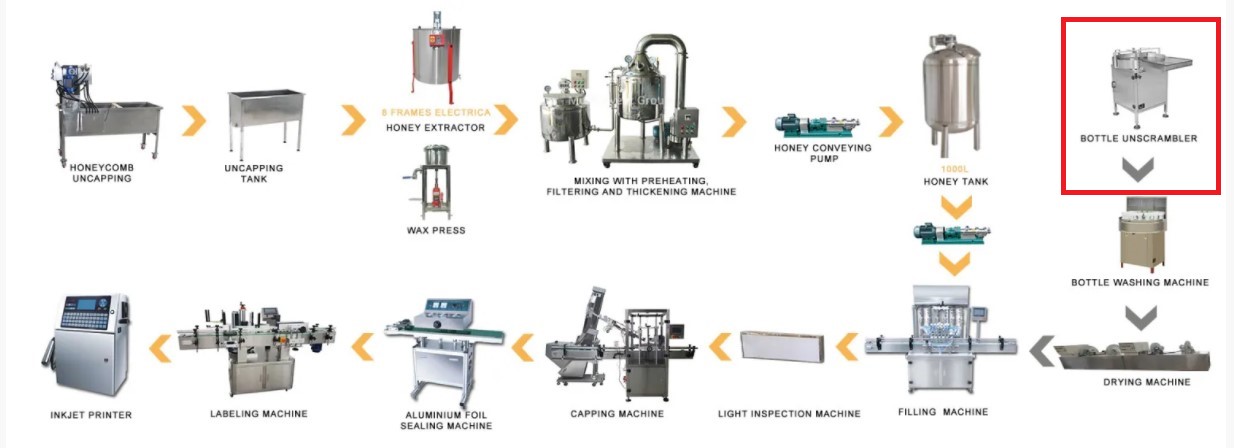

(image source: https://www.beesequipment.com/)

When using a bulk plastic bottle unscrambler, it’s important to figure out where the machine will live in your production line so you can be as efficient as possible. In order to demonstrate this, we are going to be using the example of a honey production facility. For this instance, the bulk plastic bottle unscrambler is built into packaging lines in order to feed downstream processes, including filling, inspection, capping, labeling, etc.

Another important thing to note when looking at our example is that the unscrambling may not be inside the actual production line. In this example, the bulk plastic bottle unscrambler is outside of the actual production line. The bottles are scrambled and then washed and then fed into the filling unit at the same time. This can help with the footprint of your production facility as well.

Examples of a bulk plastic bottle unscrambler.

To actually see the bulk plastic bottle unscrambler in action see the video below:

In the video above, the bottles are fed up in from the hopper into the unscrambler. Where the bottles are sorted out and then dropped into the outfeed and oriented into the conveying unit area.

These machines may also have an air rinser to remove any particulates and/or static from the bottle before going into production.

Manufacturers:

Some of the manufacturers that we look for are

- Omega

- Kaps-all

- Pace

Questions to consider:

- Some of the key features to consider when you are purchasing a used bulk plastic bottle unscrambler include:

- Is there any additional tooling for varying sizes?

- Will the machine orient bottles for you?

- What are the minimum and maximum sizes of bottle the machine can run?

- What is the bowl diameter?

- What shapes can the machine run?

- What size and shape was the last bottle run?

- Will the bottle be printed or unprinted?

- Are there any additional options included in this machine. Such as: infeed/outfeed conveyor, hopper, bottle counter, bottle orienter

- Are there any change parts available?

Shipping Your Bulk Plastic Bottle Unscrambler

No matter if you are buying or selling a bulk plastic bottle unscrambler, coordinating shipping is a step you will have to consider. When coordinating shipping ensure you have all components and everything is properly secured and strapped prior to shipping.

Additional Items with your Bulk Plastic Bottle Unscrambler:

When you are looking to add a bulk plastic bottle unscrambler, you may also need to add additional pieces to your production line. Such as:

- Filling

- Inspection

- Capping

- Labeling, etc.

For more information regarding bulk plastic bottle unscramblers and to get started on your next project, please reach out by filling clicking the button below.

Contact