A Complete Guide to Conveyor Metal Detectors

Helping You Protect Your Products, Customers, & Brand Image

Metal detectors with conveyors are a type of product inspection equipment that are used to detect even the smallest pieces of metal inside of a product, and automatically remove defective items from the production line. These machines are usually installed in a packaging or processing line to check products as they move through the production and packaging stages of the process.

This guide will cover everything you need to know about metal detectors with conveyors, including the following

- How do metal detectors with conveyors work?

- Types of reject methods

- Types of contaminants

- Will my metal detector work if my packaging contains metals?

- The importance of calibration

- Production line example

- Manufacturers

- Questions to consider when buying a metal detector

How do metal detectors with conveyors work?

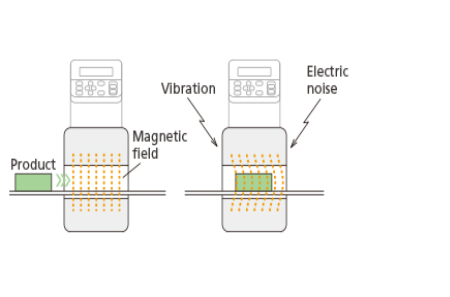

Metal detectors function by looking for magnetic field fluctuations when a product passes through the metal detector head. If any metal is detected during this stage, the machine will send a reject notice and the product will be removed from the conveyor using a reject method.

Photo Source: Mettler Toledo

Types of Reject Methods

Metal detectors are equipped with a reject that will remove a product from the conveyor once metals have been detected. This is an important element of metal detectors and keeps faulty products from getting packaged and processed along with the uncontaminated ones and ultimately saving your company time and money by avoiding recalls. There are a variety of types of reject methods, including the following.

Reject methods

Air blast reject - uses a blast of air to remove any contaminated items from the conveyor. This is a fast way to remove products since production doesn’t have to be paused and works best with lightweight materials.

Retracting belt reject - this reject mechanism works by retracting the machine’s conveyor belt so that the contaminated product will fall into a reject bin below instead of continuing on down the production line.

Drop flap reject - the reject arm for this method rotates, so that instead of moving forward, the product is dropped backward and moved away from the moving conveyor.

Source: Lock Product Inspection

Auto-reverse reject - once a contaminated product is detected, the conveyor will stop and then reverse directions so the product can then be picked up by an operator and put into a reject bin. This reject option is a good fit if you have a semi-automatic production line.

Source: Simms Engineering Systems

Push bar reject- uses a bar to push the faulty product off of the conveyor and into a reject bin and is good for heavier and rigid packages

Diverter reject - this method is similar to the push bar but uses a larger arm so will work well with fragile or bottled products

Source: Kleenline

Belt stop reject - the conveyor belt will stop once a bad product has been detected so that it can then be removed

The reject method of a metal detector varies from machine to machine and ultimately depends on what kind of product you are running. If you are running heavy or fragile items, you will need a gentle reject method, like the auto-reverse reject. Or if you are running lighter items at a high speed, a quicker reject will work best, such as the air blast reject. We always recommend sending in a sample of your product so that our sales team can ensure the equipment you’re looking to buy will fit your production’s needs.

Types of contaminants

There are three main groups of metallic contaminants

Ferrous - this type of metal is both magnetic and conductive, making it easy to detect

Non-ferrous - unlike ferrous metals, this is non-magnetic but is a good conductor so it is relatively easily detected

Stainless steel - this is the most difficult metal to detect since it is both non-magnetic and a poor conductor

Will my metal detector work if my packaging contains metals?

After mentioning the types of metals that can be detected within products, you may run into the question, “will my metal detector detect metal contaminants if my packaging contains metals?” The answer is yes! This is a concern many of our customers face, and we have an easy solution for you.

If your product’s packaging contains aluminum foil or other non-ferrous metals, you will want to use a ferrous in-foil metal detector. These types of metal detectors will overlook the presence of metals in fresh or frozen packaged products and accurately detect ferrous metals such as iron and steel. Another option for solving this problem is using x-ray inspection.

The importance of calibration

When buying a metal detector from SIGMA, upon request, we will provide a cycle-test video of the machine running to guarantee it’s in working order. This just ensures that the machine is running, it does not mean it is properly set up to detect metals.

Once the metal detector arrives at your facility, it must be correctly calibrated or validated to fit your particular process and product. This setup can be done by an OEM or a third-party company. To learn more about metal detector setup and its importance, click here.

Production line example

Below is a photo example showing how a metal detector can fit into your production line.

Something important to note is if your packaging process has multiple steps or stages, it is helpful to have multiple metal detectors. Detecting faulty products as early on in the production instead of at the final stage will save you time and money. The final stage is the worst place to find contamination since you have invested ingredients, labor, machine hours, and packaging.

Some real-life examples of recalls due to metal contamination are

- Hormel recalled 228,000 pounds of canned pork and chicken products for possible metal contamination

- Tyson recalled 11 million pounds of frozen chicken strips

- Weis Markets announced a recall of more than 11,000 containers of ice cream products due to possible contamination with metal filling equipment parts.

Most OEMs recommend placing metal detectors at any spot where incoming raw materials are or any size reduction process such as frozen clock chippers, slicers, dicers, and grinders

Manufacturers

Some recommended manufacturers we sell are

- Mettler Toledo

- Thermo Fisher

- LOMA

- Fortress

- Goring Kerr

Questions to consider when buying a metal detector

- What is the distance between the bottom of the aperture to the top of the aperture?

- What is the effective height from the top of the conveyor belt to the top of the aperture opening?

- How wide is the opening through the metal detector head?

- How long is the conveyor belt?

- How wide is the conveyor belt?

- What is the distance from the top of the conveyor to the floor?

- Does this unit have a product reject?

- What type of product reject does this unit have?

- What type of conveyor belt does this unit have?

- What is the version number of the software used in the metal detector head?

- What is the version number of the firmware used in the metal detector head?

Summary

Metal detectors are a must-have if you are packaging or processing equipment. They offer protection and assurance for the products your customers consume, your brand’s image as well as keep liability risks low.

SIGMA offers the expertise and inventory to help you buy or sell your metal detector conveyor today.

Looking to Buy Looking to Sell