Description

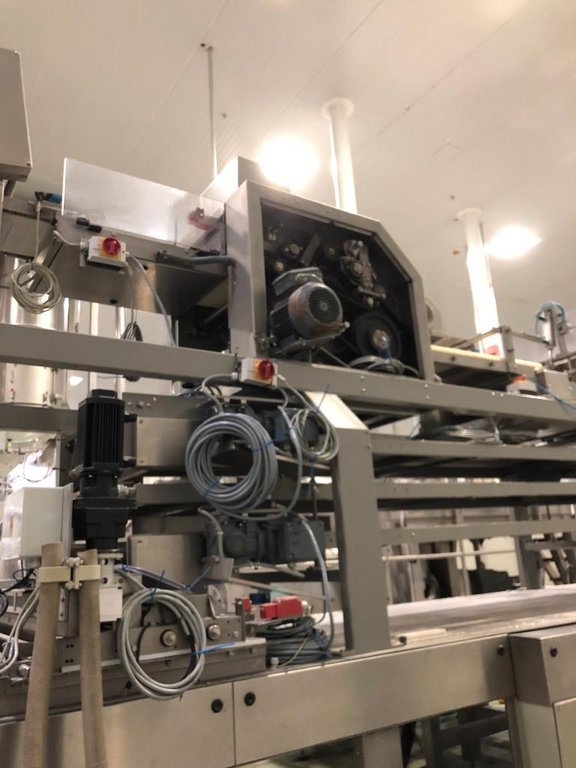

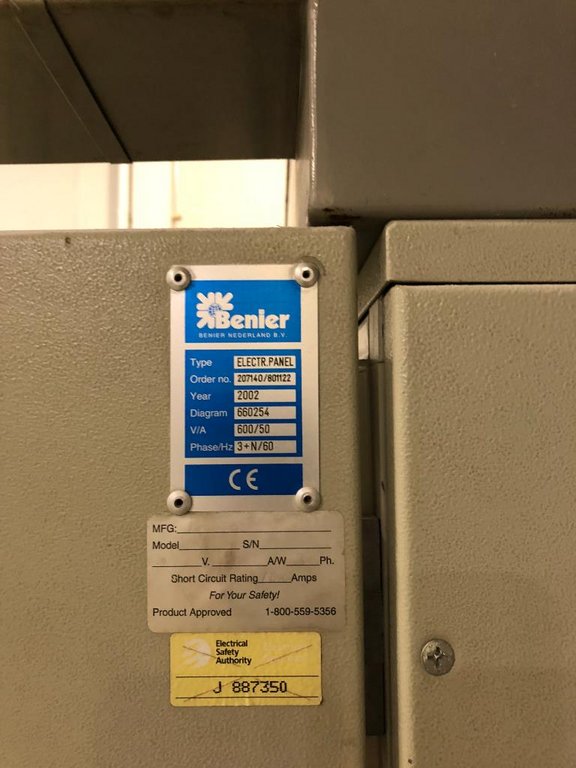

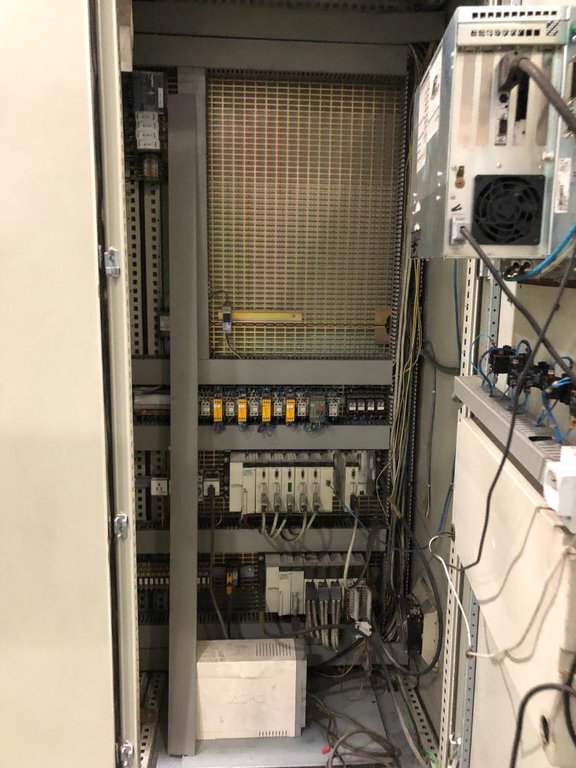

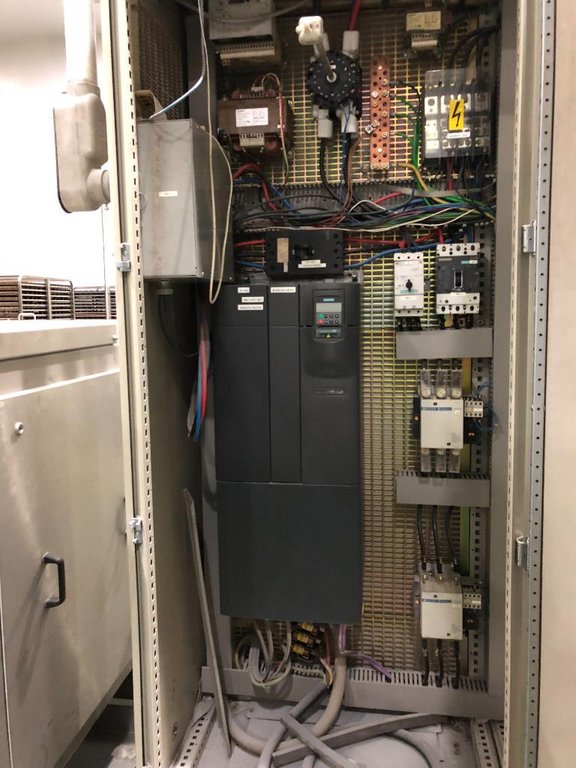

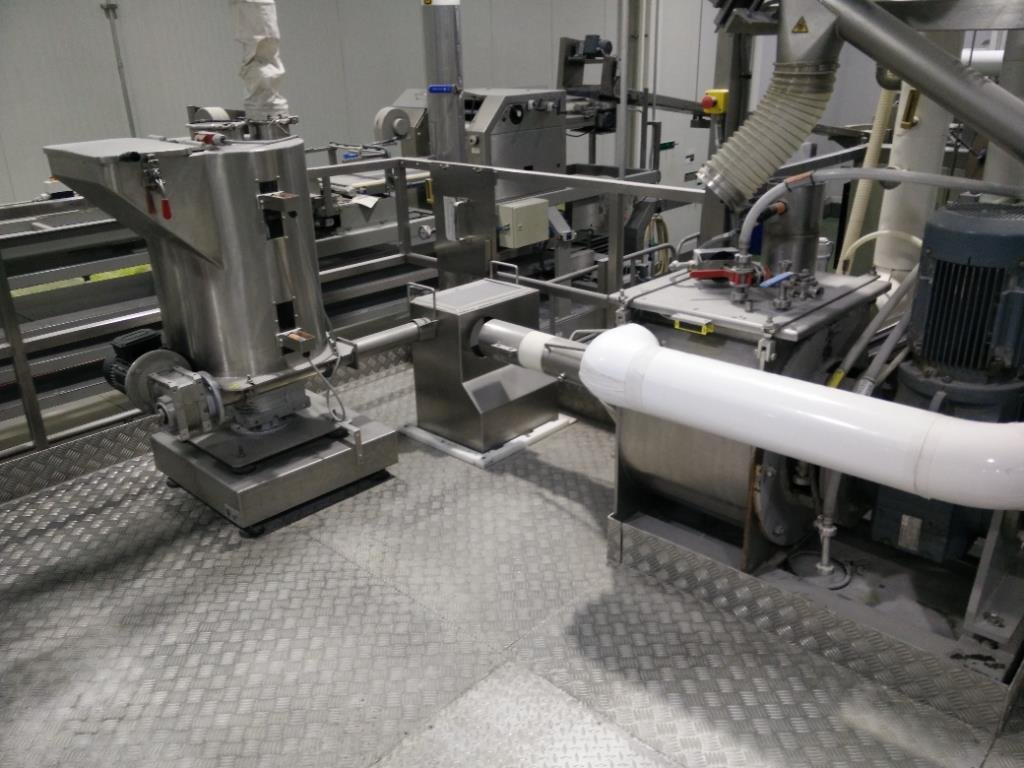

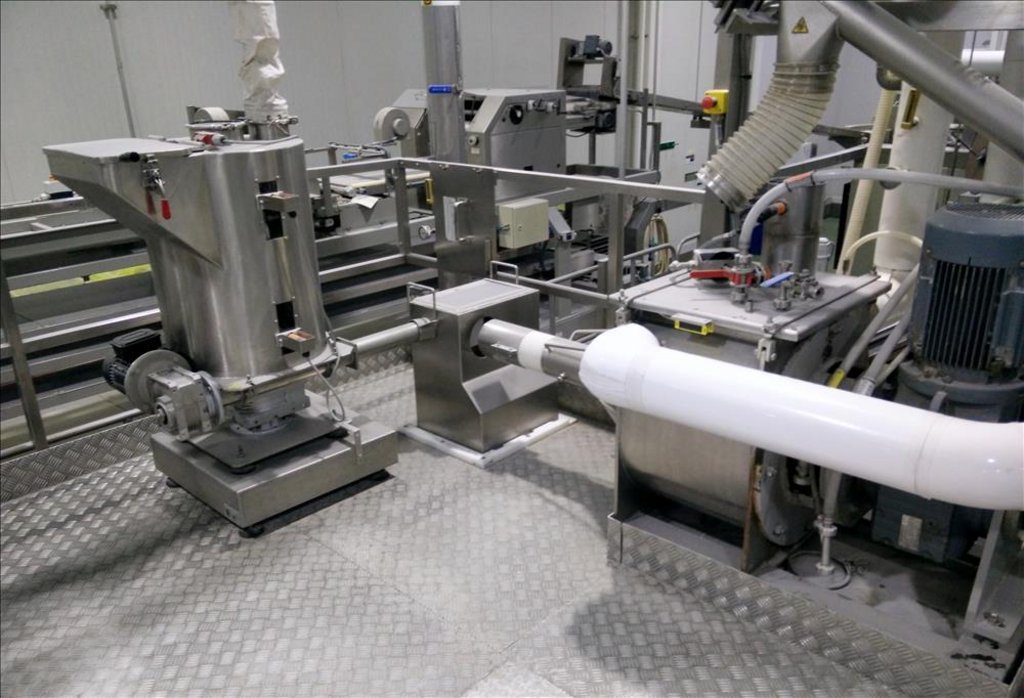

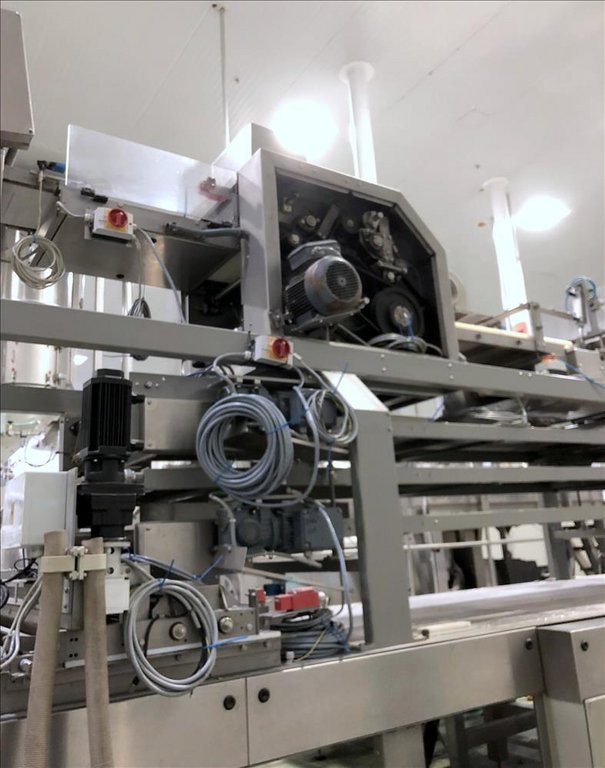

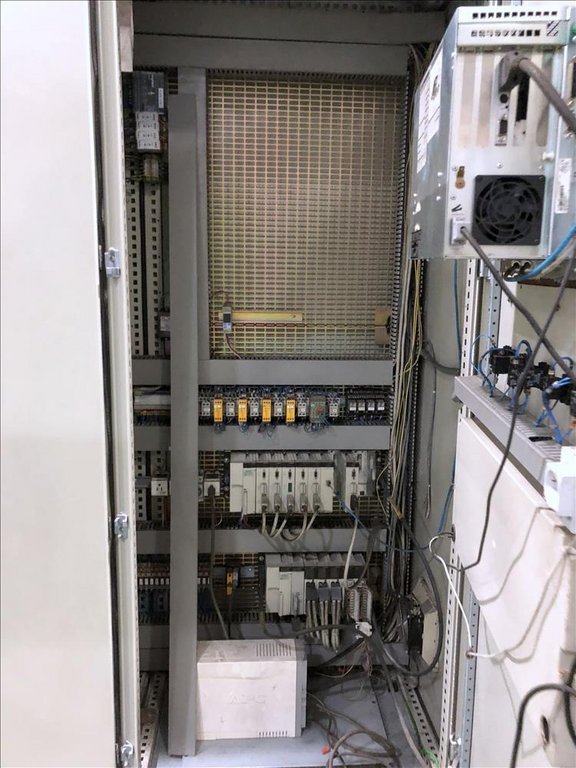

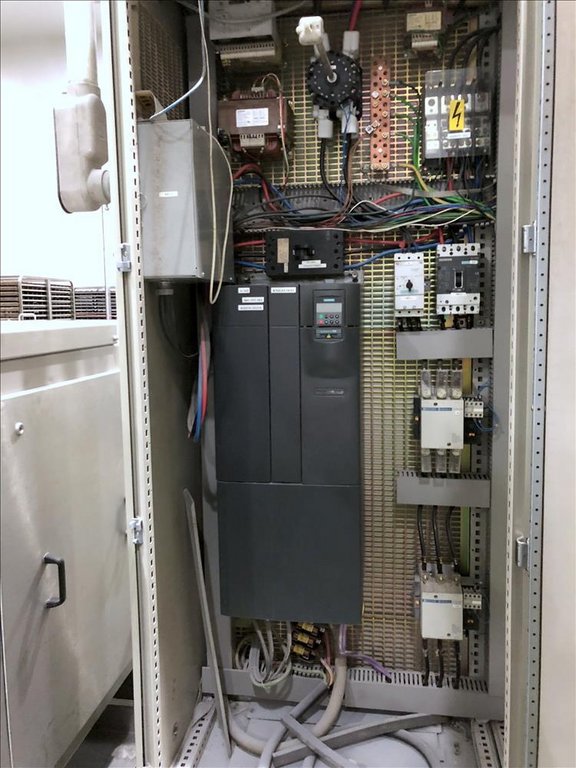

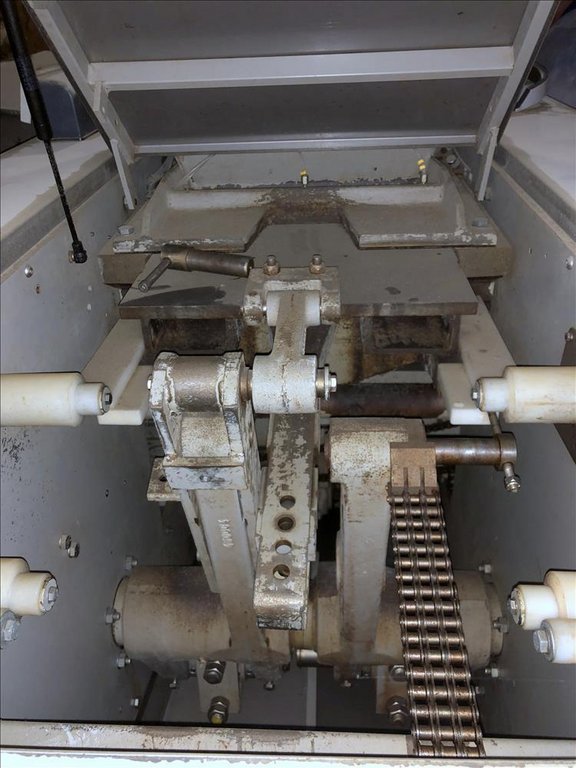

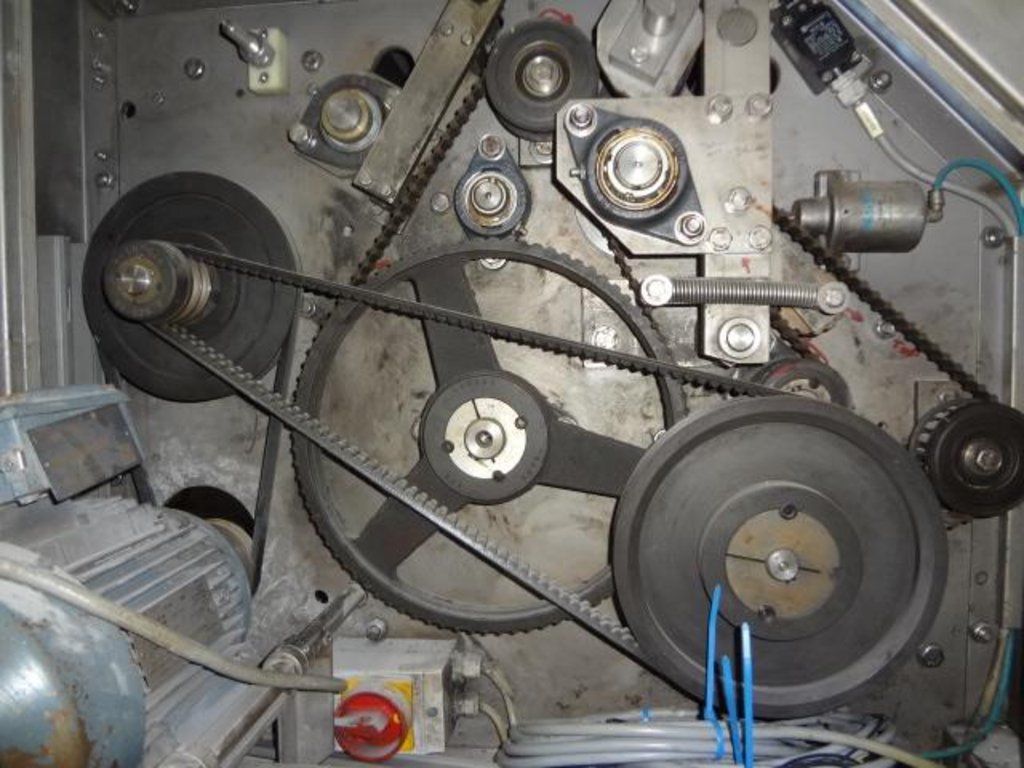

Used Bernier Baguette Roll Line with:

- Output varies by size of each piece:

- 600 grams per piece - 3000 pieces per hour

- 350 grams per piece - 3200 pieces per hour

- VMI mixer and components, output 1800 kilograms per hour

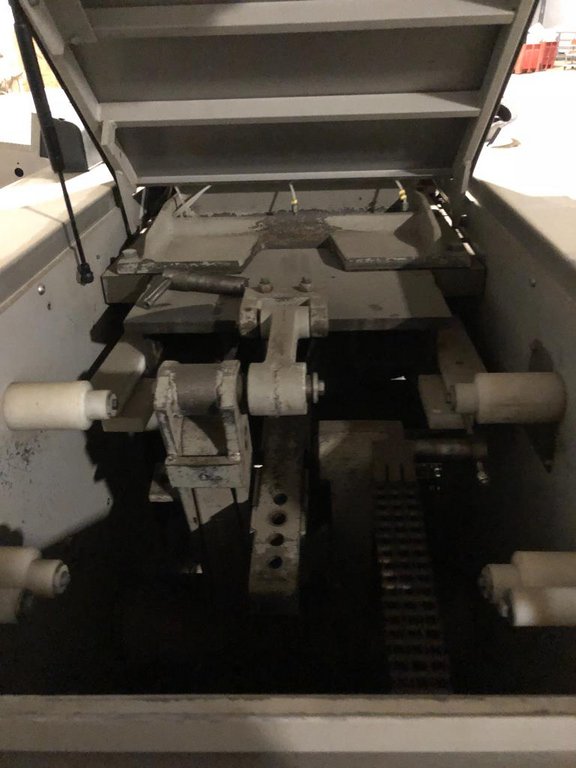

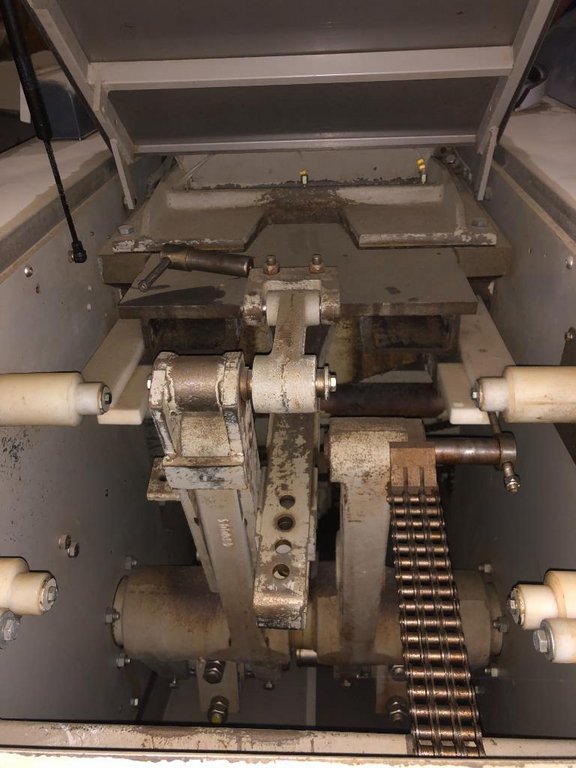

- Divider B9350

- Pre-shaper

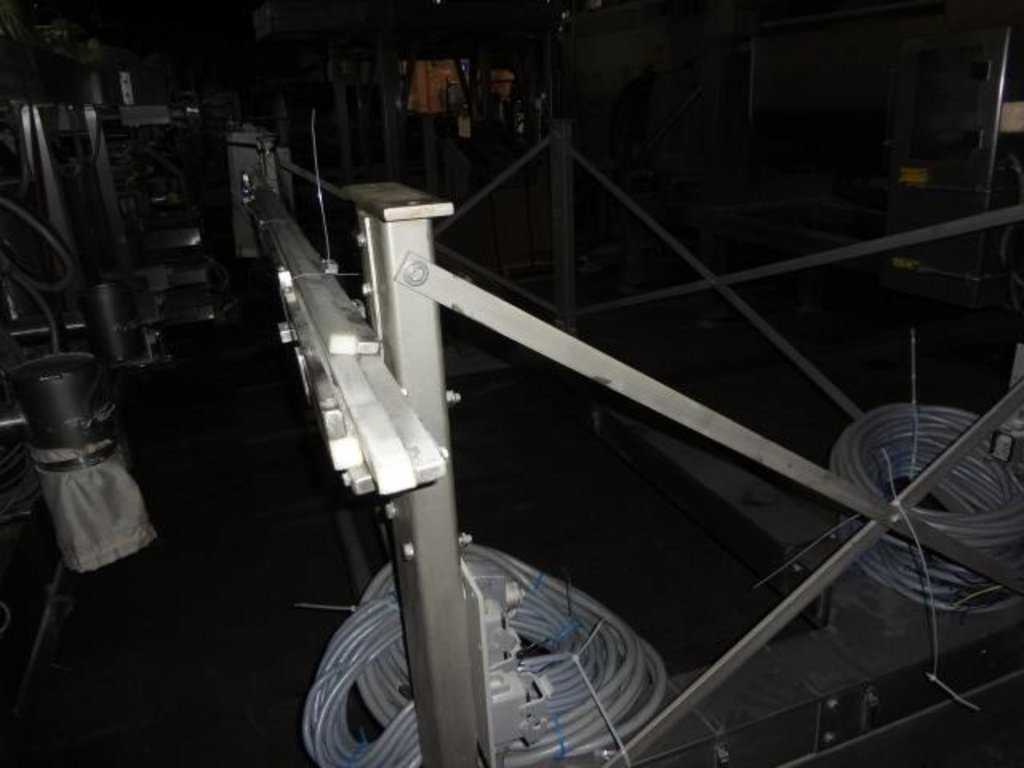

- Double Indexing Infeed System

- First Prover Type 800N

- Isolation Box

- Climatisation Type ACK-ED Conveyors

- Curve 90 degree Conveyor

- Indexing Conveyor

- Moulding table

- CCD Unit

- Dough Weight: 250 - 465 Grams (8.81 oz - 16.40 oz)

- Cutting Pattern: 1, 2, 3, 4, 5, And 6 Parts

- Pan Dimensions: 800mm x 600mm x 40mm (31.49" x 23.62" x 1.57")

- Product cutting dimensions:

- 1 Piece 460g (16.22 oz) 577 mm(22.7 inch)

- 2 Piece 300g (10.58 oz) 290 mm(11.41 Inch)

- 3 Piece 130g (4.58 oz) 170 mm (6.69 Inch)

- 4 Piece 80g (2.82 oz) 130 mm (5.11 Inch)

- 5 Piece 60g (2.11 oz) 110 mm (4.33 Inch)

- 6 Piece 40g (1.41 oz) 80mm (3.14 Inch)

- First Prover Type 800N:

- Net Load: 800 Dough Pieces

- Proof Time: 16 Minutes And 13.3 - 10.7 - 8.0 - 5.4 Minutes

- (75) - 12 Portioned Pocket Swings

- Climatization:

- Ambient Temperature: 21°C (69.8°F)

- Ambient Humidity: 50% RH

- Dough Temperature: 20°C (68°F)

- First Prover Temperature: 21°C (69.8°F), Max 2°C (35.6°F) Above Dough Temperature

- First Prover Humidity: Max 60% RH (No Cooling)

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.