A Guide to Centrifuges

How Utilizing A Centrifuge Can Improve Production

A centrifuge is used to separate materials according to their differences in gravity. A centrifuge rotates around a fixed axis, applying a force perpendicular to the axis.

Topics we will cover:

- Types of Centrifuges

- What is Centrifugal Force

- Rotor Types for A Centrifuge

- Why You Need A Balanced Centrifuge to Work

- How to Balance A Centrifuge

- Industries that Use a Centrifuge

- Where Does A Centrifuge Fit In a Production Line?

- Manufacturers

- Questions to Ask Before Purchasing or Selling a Centrifuge

Types of Centrifuges:

The two main types of centrifuges include a vertical bowl and a horizontal pusher, which are both used to separate liquids from suspended solids. When centrifugal force is applied, denser substances separate to the bottom and lighter objects tend to move to the top (or to the center in the horizontal pusher type). Most centrifuge systems are continuous in operation, but batch centrifuge machines are also available.

These machines are highly technical and when looking for one, you must know what your uses are going to be and what the requirements are of the machine before purchasing.

What is Centrifugal Force

The official definition of centrifugal force is an apparent force that acts outward on an object moving around a center, arising from the object’s inertia. An example of this is a merry-go-round. When you are on the merry-go-round, the outward pull you feel as the merry-go-round spins is the centrifugal force at work. A centrifuge uses this form of inertia at high velocities (thousands of rotations per second) to separate the particles (the pellet) in the test tube for further utilization.

Rotor Types for A Centrifuge:

When deciding on a centrifuge for your production needs, the important thing to consider is where you need your sediment to settle. This will help determine which type of rotor you will need. The two most common types of rotor designs are the fixed angle rotor and the swinging bucket rotor.

The fixed angle rotor does what it describes - it holds test tubes in a fixed position relative to the vertical axis of rotation. This can be up to a 45-degree angle. The centrifugation will then cause particles to settle at the side or bottom of the tube.

The swinging bucket design allows the tubes to swing out from the vertical resting position to become parallel to the horizontal during centrifugation. Because of this, the sediment will settle at the bottom of the tube.

When deciding between the two options, it’s important to note that the fixed-angle rotors are ideal for when you need to test or utilize the pellet (the sediment at the bottom of the test tube). The swinging bucket rotor is best for separating large volume samples and you can run the machine at low speeds.

Why you need a balanced Centrifuge

When operating a centrifuge, everything inside of the centrifuge needs to be balanced. This means that the same amount of liquid needs to be in the test tubes within the centrifuge. In addition, the number of test tubes loaded into a centrifuge needs to be balanced on either side of the centrifuge to work accurately. If not, the readings can be inaccurate and can damage the machine. Should you have an odd number of tubes to test, use another test tube if a similar volume to balance everything out.

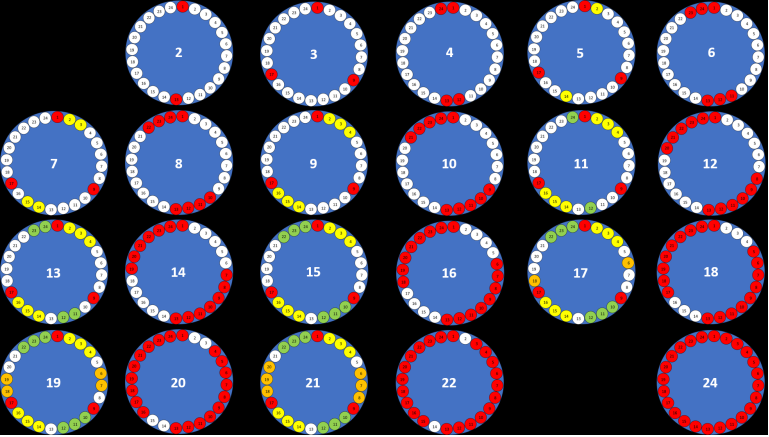

How to Balance A Centrifuge

There are multiple ways to balance a centrifuge. It will depend on the number of test tubes your centrifuge can hold. Below is an example of a centrifuge that holds 24 test tubes as that is the most common type for the food packaging and processing industry:

It’s also important to note when using the centrifuge to be careful when taking specimens out of the machine as jostling can mix particles back together.

Industries that Use a Centrifuge

When most people think of the industries that use a centrifuge, they think of the medical field. This is where most people have experienced or seen them before, however, centrifuges have a wide range of uses, including:

- Medical

- Environmental Chemical processing that produces raw products

- Pharmaceutical and Biotechnologies

- Fuels and Biofuel

- Food processing

- Dairy

- Meat rendering

- Juices

- Beer

- Wine

- Liquor

- Miner and mineral processing

Where Does A Centrifuge Fit In a Production Line?

While a centrifuge can be very helpful when it comes to quality control, these machines are not usually part of an active production line and are typically stand-alone units. They do not necessarily have an upstream or a downstream as they can be used to test at the end of a production line or used to pull extracts prior to those extracts being placed into a product. The upstream and downstream will depend on your product and where you plan to use the machine within your production.

Top Manufacturers:

There are many different manufacturers to build out a centrifuge and your application will depend on which manufacturer is right for you. However, below are some of the preferred manufacturers:

- Flottweg

- GEA

Questions to Ask Before Purchasing or Selling a Centrifuge:

Here are some questions to consider before buying or selling your centrifuge:

- What type of centrifuge is the machine?

- Benchtop?

- Refrigerated Large Capacity?

- High-Speed Refrigerated?

- Preparative Ultra Centrifuge?

- Analytical Ultra Centrifuge?

- Other?

- What industry was it previously used in?

- Are the rotors interchangeable?

- What volumes will you need to work with?

- Are samples temperature-sensitive that you need to test?

- What is the maximum g-force the centrifuge can generate?

Summary

In conclusion, a centrifuge can be a huge asset to any team that needs to extract specific parts of their product. Whether that be testing for quality control, gathering extracts or concentrates, or somewhere in between, our team at SIGMA Equipment can help you find the centrifuge you need for your next project.

To get started, contact us at 812-303-8383 or click the button below to fill out our contact form.

Contact