Used All-Fill SHA Auger Filling Capping and Packaging Production Line

Click image for full size.

Having trouble viewing media for this All-Fill Inc. SHA?

Click here for full page view of all Equipment Media (36)

Click here for full page view of all Equipment Media (36)

Equipment Details

| Equipment # | E325291 |

| Item | All-Fill SHA Auger Filling Capping and Packaging Production Line |

| Category |

Production Line Prepared Food Production Line |

| Manufacturer |

All-Fill Inc. All-Fill |

| Model | SHA |

Equipment Description

Used All-Fill Powder Filling Line with:

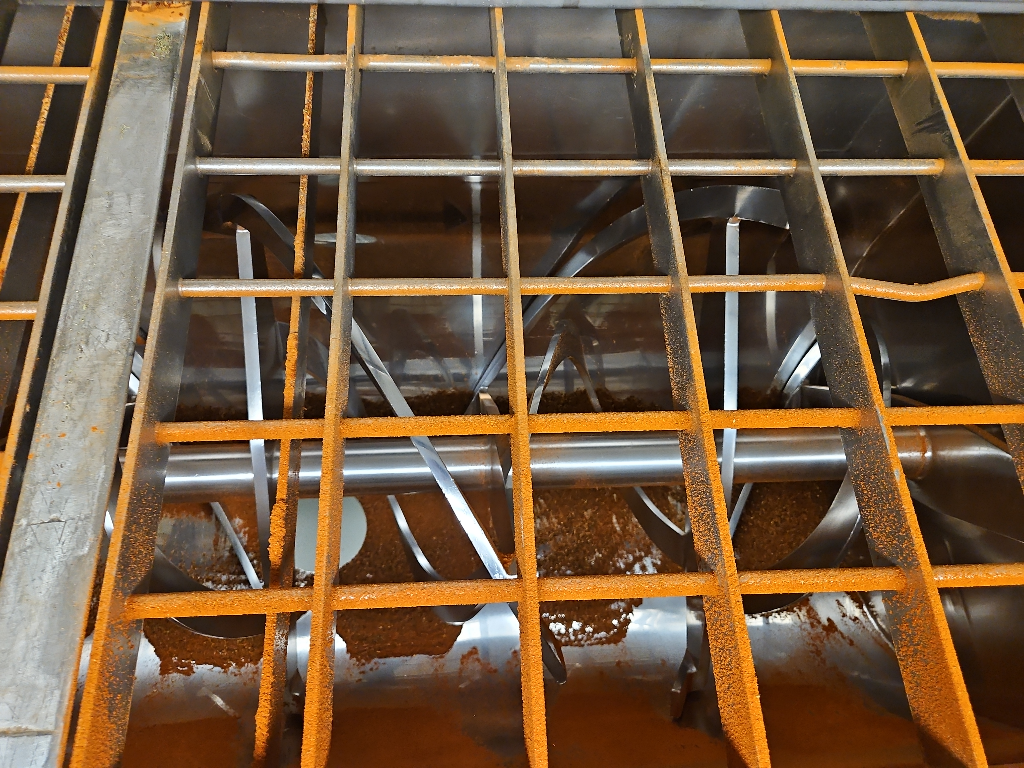

- Lowe C-30 Ribbon Blender:

- Capacity: 30 cubic feet

- Single shaft ribbon agitation

- 304 stainless steel construction

- Bottom center discharge diameter: 5 inches

- Infeed height: 78 inches

- Product discharge height: 43 inches

- Drive motor: 15 horsepower

- Flexicon Auger Conveyor:

- Auger dimensions:

- Diameter: 3 inches

- Flights: 3.5 inches

- Length: 9 feet

- Discharge height: 87 inches

- Motor: 3 horsepower

- Auger dimensions:

- All-Fill SHA Automatic Auger Filler:

- Production speed: up to 40 containers per minute depending on size and application

- Up to 100 programmable product memory

- Chain product conveyor:

- Length: 96 inches

- Infeed/Discharge height: 37 inches

- Adjustable guide rails

- Color touch screen HMI

- Allen-Bradley PLC controlled

- Mechanically adjustable height head

- Dustproof cover infeed duct

- Stainless steel contact parts

- Air requirements: 2 scfm @ 60 psi

- Electrical: 3 Phase, 60 Hz, 230 Volts

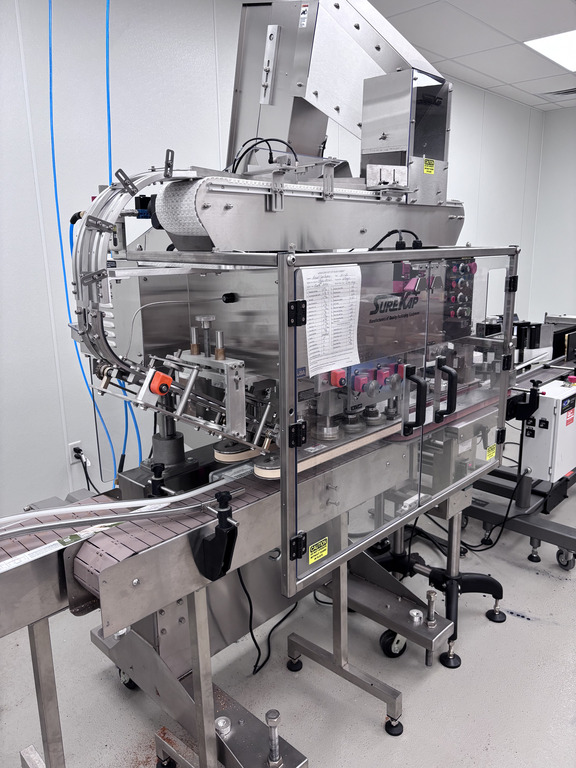

- Surekap SK6000-BF6 Spindle Capper:

- Capacity: up to 50 bottles per minute

- Six spindles

- Caps & cap size range:

- 400, 410 & CRC caps

- Minimum: 8 mm

- Maximum: 70 mm

- Stainless steel floor level hopper capacity: 4 cubic feet

- Single handle container height adjustment: from low jars to 1 gallon container

- Stainless steel frame conveyor:

- Length: 120 inches

- Width: 4.5 inches

- Air requirements: 1 - 2 CFM @ 60 - 80 psi

- Electrical: 3 Phase, 60 Hz, 120 Volts, 15 Amps

- Enercon Superseal 75 Induction Sealer:

- Sealing chamber dimensions:

- Length: 13.5 inches

- Width: 2 inches

- Mounted on stainless steel C-style frame

- Electrical: 1 Phase, 50/60 Hz, 208 Volts, 7.5 Amps

- Sealing chamber dimensions:

- Rotary Accumulation Table:

- Table diameter: 48 inches

- Infeed height: 37 inches

- Variable speed rotation

- Guide rail width: 0.5 inches

- Plastic Mat-Top Conveyor:

- Conveyor belt dimensions:

- Length: 140 inches

- Width: 6 inches

- Infeed/Discharge height: 37 inches

- VFD

- Motor: 0.25 horsepower

- Conveyor belt dimensions:

- Plastic Mat-Top Conveyor:

- Conveyor belt dimensions:

- Length: 44 inches

- Width: 6 inches

- Infeed/Discharge height: 37 inches

- Variable frequency drive

- Motor: 0.25 horsepower

- Conveyor belt dimensions:

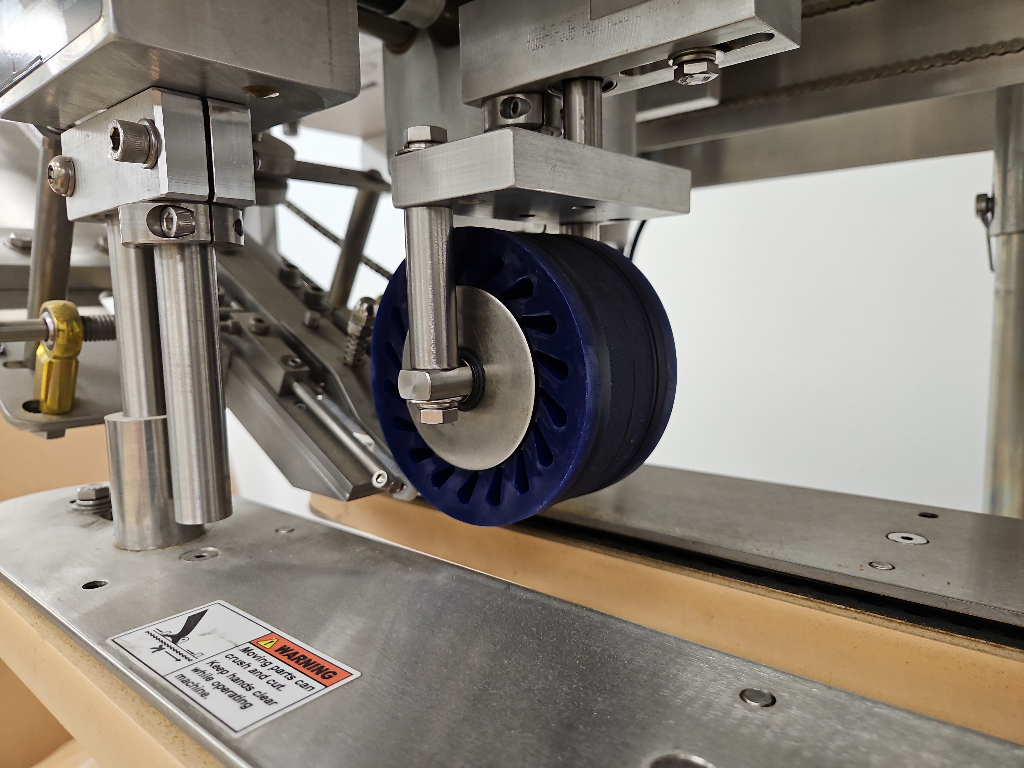

- Gap Transfer Conveyor:

- Length: 35 inches

- Gripper belt height: 1 inch

- VFD

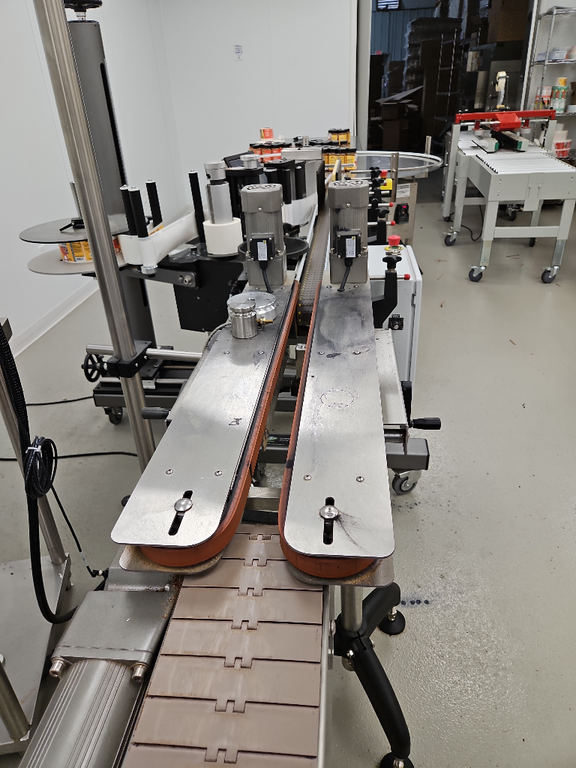

- CTM Wraparound Labeler:

- Air blow label sizes:

- Minimum:

- Width: 0.75 inches

- Length: 0.75 inches

- Maximum:

- Width: 5 inches

- Length: 5.5 inches

- Minimum:

- Merge label sizes:

- Minimum:

- Width: 0.75 inches

- Length: 0.75 inches

- Maximum:

- Width: 5 inches

- Length: 20 inches

- Minimum:

- Tamp label sizes:

- Minimum:

- Width: 0.75 inches

- Length: 0.75 inches

- Maximum:

- Width: 5 inches

- Length: 10 inches

- Minimum:

- Maximum label roll dimensions:

- Core diameter: 3 inches

- Outer diameter: 20 inches

- Electrical: 1 Phase, 50/60 Hz, 120 Volts

- Air blow label sizes:

- BestPack Case Taper:

- Throughput: up to 40 cases per minute depending on size and application

- Minimum case dimensions:

- Length: 6 inches

- Width: 4.25 inches

- Height: 3.5 inches

- Maximum case dimensions:

- Length: Unlimited

- Width: 20 inches

- Height: 20.5 inches

- Extended infeed and outfeed conveyor

Previously used in spice manufacturing facility

Location Details:

North Central USThis machine is located at a client’s facility in North Central US. To coordinate an inspection of this item, please contact your SIGMA sales team.

Call us at (812) 303-8383.Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this All-Fill SHA Auger Filling Capping and Packaging Production Line?

Request an email quote or call us at (812) 303-8383 for more information.