A Resource Guide to Glue Automatic Horizontal Cartoners

Decrease Errors & Increase Efficiencies

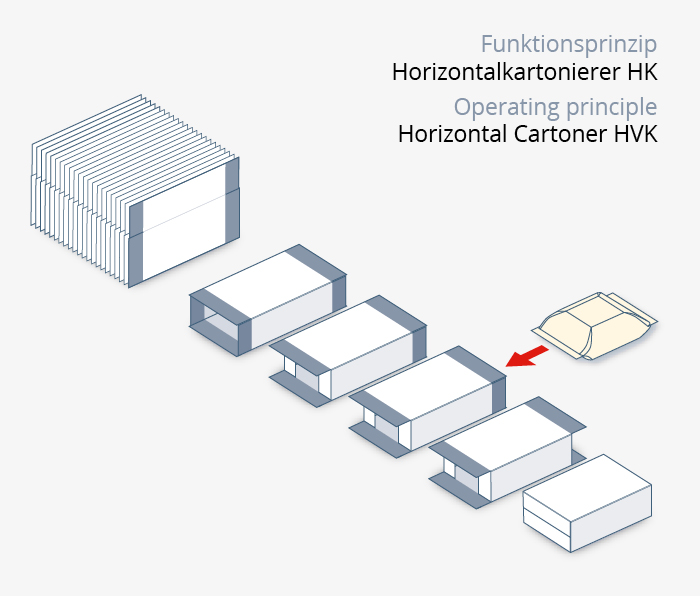

This piece of machinery is in our packaging category of equipment. A horizontal cartoning machine, also known as an end-load cartoner, takes a blank carton from a magazine, opens it horizontally into carton flights, fills it mechanically, and glues the carton closed.

(Source: https://www.dienst-packsystems.de/en/packaging-systems-products/side-load/folding-box-hk-iv.html)

Topics Include:

- Typical applications

- Use case

- Dimensions and overhead confinement

- Upstream and downstream equipment

- Information needed to choose the correct machine

- Advantages of using this type of cartoner

Typical Applications

These are versatile machines that can fit a number of applications, including:

- Vials

- Bottles

- Pouches

- Tubes

- Blister cartons

- Seal trays

Use Case:

A customer came to SIGMA Equipment looking for a continuous motion glue automatic horizontal cartoner to package their nutrition bar. SIGMA Equipment and SIGMA Integration began the work to set an ADCO 15DBC1DSWD Glue Automatic Horizontal Cartoner to their specifications. As you can see in the video below, the product is loaded and as the boxes are opened and assembled, the product is pushed into the box and the folds of the carton are then placed with glue to seal the box. The machine can now help them box 100 cartons per minute.

Dimensions and Overhead Confinement

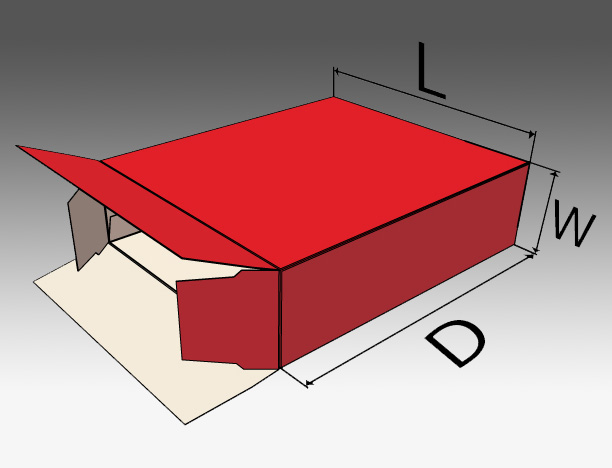

Because this machine loads cartons from the side, the dimensions of a box have to be considered.SIGMA always recommends sending samples so we can find the right machine for you. When considering dimensions for your cartons, please refer to the diagram below.

(Source: http://www.allpack.com/StructuresDefined.php)

Overhead confinement compresses the pouch so it fits the width dimension. This helps make loading the product into the case easier and prevents the cartons from being smashed or damaged.

As an example, visualize a cereal box laying on its side. As you can see, the length of the box is where the major flaps are and the width is the minor flaps. The overall depth is the distance between the ends of the carton. These measurements are not always intuitive, but paying attention to these dimensions will save you time and money when you are looking at the specifications for a machine to fit your needs.

Continuous vs Intermittent Motion

When choosing a cartoner you will need to think about what you will need from your machine. There are two types of conveyors that load the product into the carton - continuous motion and intermittent motion. Continuous motion is exactly as it sounds, a conveyor that is constantly moving to load in product between the flights to help move product faster.

Intermittent motion means that it pauses the product temporarily before loading it into the carton. Usually, these machines have a series of chambers that allow the cartons and product to be loaded in “batches”. The intermittent horizontal cartoning machine is typically best for smaller production lines while the continuous motion machines are used for those who need larger output.

Upstream and Downstream Equipment

Whether you are scaling up, updating a line, or integrating new equipment, you’ll want to look at your upstream and downstream equipment that you may need to include or update as well. SIGMA Integration has the capabilities to set up the equipment you need, test it, or integrate it into your production line.

Upstream equipment includes:

- Fillers

- Form, fill, and seal machines

- Cappers

Downstream equipment includes:

- Labelers

- Sealers

Advantages of a Glue Automatic Horizontal Cartoner

Using a cartoner can help your company leaps and bounds, but in particular, they can help increase efficiency within your packaging process. The cartoner itself requires little human intervention and employees can be redeployed in other production areas to keep staffing costs down, increase output, and keep your production costs down, making your facility more efficient.

These machines can also maintain your package integrity and this leads to higher customer satisfaction and less refunding due to damaged packaging.

However, one of the largest benefits is keeping error rates down. While the machine is not 100% error-free, it does significantly reduce the error rate caused by employees working for long durations. It also decreases repetitive motion injuries for those who were previously handloading.

What to Consider:

Going to a fully automatic horizontal cartoner is a big step in increasing production and hopefully helping you create more revenue and meet your demands. However, before doing so there are a few questions to consider before buying or selling your equipment. They include:

- What are the minimum and maximum carton dimensions?

- What are the minimum and maximum production dimensions?

- What are the bucket sizes of the conveyor?

- Are the buckets fixed or adjustable?

- Is the machine continuous or intermittent motion?

- What options do you need or come with the machine?

- No carton / no pick

- Overhead confinement

- No carton / no load

Conclusion:

Glue automatic horizontal cartoners are a great way to keep production costs down, and increase productivity. With SIGMA Equipment, we can help you find the equipment you are looking for and with SIGMA Integration we can help you integrate and update that machinery to fix your specific needs. Just click the buttons below to get started.