Bagger Only Vertical Form Fill Seal

Creating a completely automated filling and bagging system to fit your needs

Introduction:

The bagger-only vertical form fill and seal (VFFS) equipment allow companies to automate the bagging process of production. There are many types of vertical form fill and seal machines and in this guide, we will focus on the bagger-only vertical form fill and seal machine. Bagger-only vertical form fill seal equipment includes the part of a vertical form, fill, and seal machine that forms and seals the product. Fillers are not included and must be purchased in addition to the bagger-only VFFS machine.

In this guide, we will cover:

- Industries

- How these machines work

- Where they fit into a production line

- Upstream and downstream equipment

- Types of Bags

- Types of Fillers

- SIGMA Integration Case Study

- Manufacturers

- What to consider when buying and Selling

- When to use them

Industries:

These machines are useful for a variety of industries but are primarily used in:

- Bakery

- Cereal/Grain

- Chemicals

- Cosmetics

- Pet Food/Supplies

- Sauces

- Snack Foods

How These Machines Work

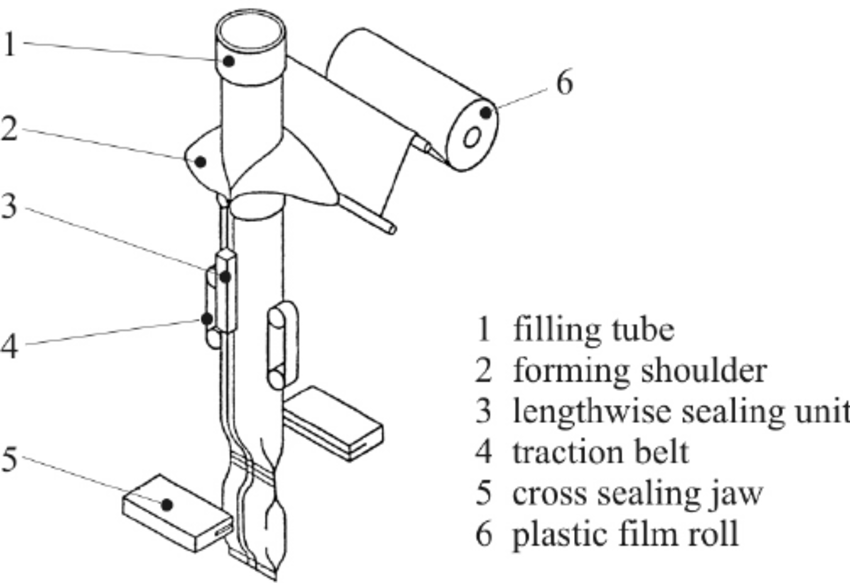

Source: researchgate.net

The above photo depicts the parts of the machine and how they play into each other. Again, it’s important to note that this category of equipment does not have a filling portion, so it is going to just make the bag, seal, and move it downstream. You will need a filler to appropriately fill the bag with product.

In order to make the bag or pouch for your product, the machine first must place the bag film over the forming shoulder while the lengthwise sealing unit forms the length of the bag. Then a traction belt on either side that make sure that the film as it's going down, goes down uniformly. The bottom of the bag will be sealed with a cross sealing jaw, forming the width of the bag. Once the bag is formed a filler can be used to fill the bag with product before the jaws close the top of the bag and send the product down the production line.

Where they Fit into a Production Line

Source: jwweigher.com

The great thing about the bagger only vertical form fill seal machine is that it can be used with other machines to create a self-sustaining production line. This means that if you are a smaller company looking to scale up and increase production, finding and integrating this machine with other upstream and downstream equipment can give you a full and automated production line.

Upstream and Downstream Equipment

Because these machines are typically in the middle of a production line, there are multiple upstream and downstream equipment pieces to consider when adding or updating equipment in your production line. This equipment must also work with your bagger only vertical form fill seal equipment and integration or additional tooling may be needed. SIGMA Group’s SIGMA Integration division can assist with any setup or integration needed.

Upstream Equipment:

- Mixers

- Tanks

- Conveyors

- Depositors

- Fillers

Downstream Equipment:

- Takeaway Conveyors - Accumulation Tables

- Metal Detectors

- Checkweighers

- Case Erectors

- Case Packers

- Case Sealers

- Cartoners

- Palletizers

- Stretch Wrappers

Types of Bags

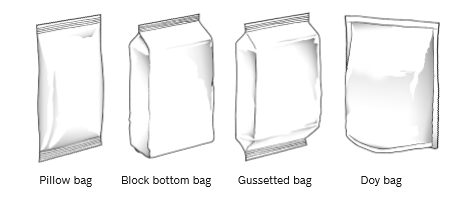

As you’ve walked up and down the grocery store aisles, you’ve probably noticed all of the different types of bags that your favorite snacks and foods are in. All of these bags have a purpose and are based on your product. To give you the best recommendation for the type of film, seal, and bag you will need our team regularly recommends sending any samples available to our team.

http://mechwellind.com/Products/VFFS_Packaging_Machine

The most frequently used bags:

- Pillow

- Gusset/ Flat bottom

- Stand Up

- Doy

However, there are also more unique bag types available including:

- Tetrahedron

- Saddle

- 3-side seal

In addition to this, there are also several additional options you can add including, but not limited to:

- Zippers

- Holes

- Degassing valves

Types of Fillers:

There are multiple types of fillers that can go along with these units, so because of that and your pouch/bag type, you will need to consider which filler is the best for your needs. Below are the different types of fillers available:

- Volumetric Filler - This type of filler is designed to work at high and low speeds while filling a container to a preset volume. Volumetric filling machines are based on a self-priming cylinder that determines the filling volume and are primarily used for liquids.

- Multi-head Filler- This type of filler is designed for those who need high speed and high volume filling while keeping their product accurate. These feeder pans will then transport product to the weigh bucket where it will be weighed and measured.

- Auger and Incline Auger Filler- This type of filler uses the rotation of an auger to measure out the proper amount of product and then dispenses it into a container. Auger filling machines are commonly used for filling dry products, powders and granules. Auger filler systems are relatively closed, making them a good choice for very fine powders, which can release airborne particles into other systems.

SIGMA Integration Case Study

SIGMA Integration worked with our SIGMA Equipment sales team to provide a customer with the necessary bagger only vertical form fill seal equipment they needed to individually package oats for consumer use. With the help of the equipment and our technical skills and experience, the customer was able to move from hand loading to automating their process and increasing their production rates.

To see more about this case study and how SIGMA can help with your integration needs, click here.

Manufacturers:

Below are the manufacturers of the bagger only vertical form fill seal:

- Weighpack

- Ilapak

- Syntegon

- Triangle

- Ishida

- Hayssen

- Matrix

- All-Fill

What to Consider When Buying or Selling

No matter if you are looking to buy or sell a bagger only VFFS, here are some things you should consider:

When selling a bagger only VFFS

- What was being run through the machine? Do they have samples?

- Are they selling any machinery that works in conjunction with this?

- What change parts will this come with?

- Does it come with any special bag options? (Zipper, gas flush, etc.)

- What type of bag can this machine run?

- What is the width of the sealing bar?

- What are the electrical requirements?

When buying a bagger only VFFS

- What kind of product are they running? (will determine change parts)

- What kind of filler are they using? Will they need to get a filler?

- Bag sizes and options needed (will determine change parts)

- What is your desired output rate?

- What type of motion are you looking for?

- Type of bag you will need for production

- What is the width of the sealing bar you will need?

- What are your minimum and maximum bag dimensions?

- What are your minimum and maximum film roll width?

- Do you need any extra options?

- What electrical requirements do you need?

Conclusion:

The bagger only vertical form fill seal machine is complicated and requires a strong understanding of your needs to select the proper machine. Because this machine does not include a designated filler, it gives you more customization but can also require more setup and integration. Also, because of the multiple filler options, it is best to determine which option meets your requirements, before purchasing a piece of equipment. SIGMA Equipment is ready to help you with the next purchase of your bagger only VFFS, select one of the buttons below: