An Overview of Wraparound Pressure Sensitive Labelers

The Key to Simplifying the Labeling Process While Remaining Cost-Effective

Wraparound pressure sensitive labelers play a crucial role in various industries by simplifying the labeling process. These machines apply labels to cylindrical containers without using heat, water or special solvents, providing an efficient and hassle-free labeling experience. These machines use labels that essentially act as stickers and work best on round containers.

In this equipment guide, we’ll cover the following:

- Equipment Definition

- How a pressure sensitive label gets on a container

- Rotary vs. Inline Machines

- Where to find in a production line?

- Additional Equipment

- Preferred Manufacturers

- Industries Used In

- Key Talking Points

- Summary

What is a Wraparound Pressure Sensitive Labeler?

A Wraparound Pressure Sensitive Labeler conveys a cylindrical container or bottle between a rotating belt and a pressure plate. During this process, a label is dispensed and follows the product to wrap around the container. Pressure sensitive labels have a film backing, which needs to be removed before application to uncover the adhesive on the back of the label.

How a pressure-sensitive label gets on a container

[Source: Packaging Digest]

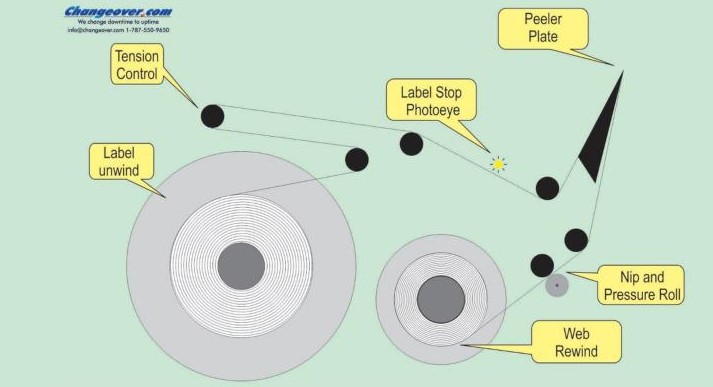

Pressure sensitive labels bring their own adhesive. Because of that, they have a rolled-up paper or plastic backing web to keep the labels from sticking until they are applied to the container. The most important part of a pressure sensitive labeler is transferring the label from the backing web to the package.

As a container is coming into the machine, the label roll unwinds over a tension control roller. Consistent tension control is critical to achieving consistent label application on the product.

There are a series of guide rollers that carry the labels with its web backing through the labeler and to the peeler plate. The peeler plate, sometimes called a knife edge, reverses the web direction, causing the label to separate from the web. The label will then continue forward and onto the container.

The nip-and-pressure roll pulls the web through the labeler and the empty web is collected on the rewind reel.

To avoid interfering with the label application, these machines come equipped with spacing wheels or worm screws. They ensure containers are properly spaced as they are conveyed into the labeler.

Rotary vs Inline

These labelers are designed to be either inline or rotary machines.

Inline Wraparound Labelers

Inline machines are ideal for simpler operations. These units label containers in a line as they are conveyed into the machine.

Rotary Wraparound Labelers

The rotary version of these machines are for those who prioritize speed and efficiency. These machines are more complex and utilize turrets that rotate bottles to increase labeling speeds.

[Source: Shorewood Engineering, Inc.]

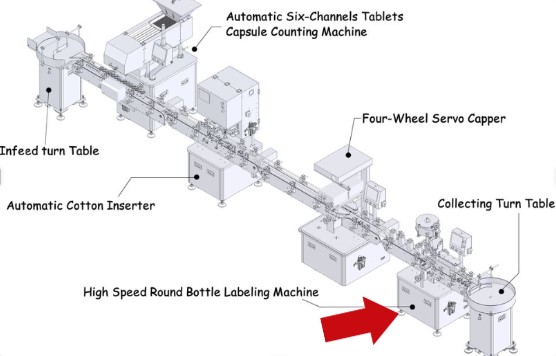

Where to find in a production line?

Additional Equipment

If you are considering purchasing a wraparound pressure sensitive labeler, you may also require certain upstream and downstream equipment to ensure a smooth production line. It's worth noting that the list provided below is not comprehensive and there may be additional equipment that could enhance your operation.

Upstream Equipment

- Filler

- Capper

- Seamer

Downstream Equipment

To explore the full range of equipment options that can complement your production line, get in touch with our team by clicking below.

Our SIGMA Integration team can integrate these labelers into your production line and can even provide customized engineering solutions to ensure it handles your product at your required metrics.

Favored Manufacturers

- ACASI

- Accutek

- CVC

Industries Used In

- Beverage

- Automotive

- Nutraceutical

- Cosmetics

Questions to consider before buying or selling:

Buying:

- Does this unit have a product photo-eye?

- What is the height of the pressure plate?

- Is the conveyor included?

- What are the machine’s electrical requirements?

Selling:

- What is the shape of the container?

- What are your label/container dimensions?

- Where will the label be placed on the container?

- What is the diameter of your label roll?

- What speeds are you looking to accomplish?

Summary

Wraparound pressure sensitive labelers adhere to a product’s surface without the need for heat, water or any special solvents. These machines make for a simple and efficient labeling process by only requiring pressure to form a bond between the adhesive and the container.

Click here to view our inventory of wraparound pressure sensitive labelers.

If you’re interested in one of these units, contact our sales team to find the machine that’s best suited for you and your product.